How does the Mini piston pump work in the vacuum preservation machine?

The working principle of the Piston Pump in the vacuum preservation machine is to continuously extract the air in the preservation chamber through the reciprocating motion of the piston to maintain the vacuum state. when the piston goes up

When moving, the air in the fresh-keeping chamber is sucked into the pump, and then when it moves downward, the air is discharged out of the pump through the exhaust port, thereby forming a certain vacuum environment in the fresh-keeping chamber.

Specifically, the working process of the Mini Piston Air Pump in the vacuum preservation machine is as follows:

1. The piston moves downward, and the suction port opens, allowing external low-pressure gas to be sucked into the pump body.

2. After the piston reaches the lowest point, the suction inlet is sealed, and a low pressure area is formed in the pump body.

3. The piston moves upward, and the sealing ring that forms the Mini Vacuum Pump separates the low pressure area from the exhaust port, and at the same time discharges the gas in the low pressure area from the exhaust port. Due to this constantly changing piston movement, the micro piston pump can continuously and gradually extract the high-pressure gas, thereby forming a vacuum environment and ensuring the normal operation of the vacuum preservation machine.

The role of the Vacuum Piston Pump in the vacuum packaging machine includes the following aspects:

1. Extract air: The Diaphragm Piston Pump generates negative pressure through reciprocating motion, and extracts the air from the package to form a vacuum state inside the package. This can extend the shelf life of food and prevent the oxidation of food by oxygen.

2. Achieve efficient sealing: During the vacuum packaging process, the micro piston pump can help the packaging material stick to the food to achieve efficient sealing. This ensures that the food will not leak during storage and transportation, maintaining the freshness and quality of the food.

3. Improve product quality: Vacuum packaging achieved through micro piston pumps can improve product quality and keep food in better shape and taste. At the same time, since the contact between food and air is reduced, the growth of bacteria and mold can be reduced, and the hygienic safety of food can be improved.

4. Convenient operation: The Mini Piston Vacuum Pump has a simple structure, small size and light weight, and is easy to install in a vacuum packaging machine. At the same time, it is simple to operate and easy to maintain, which can reduce equipment costs and maintenance costs.

Technical Specification

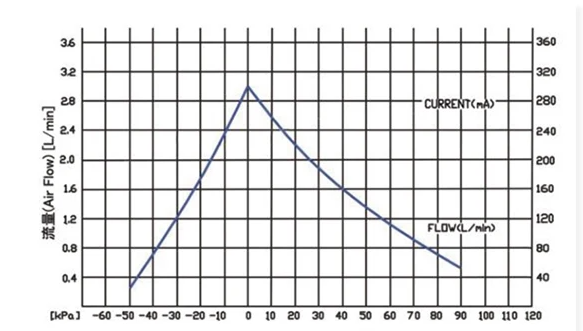

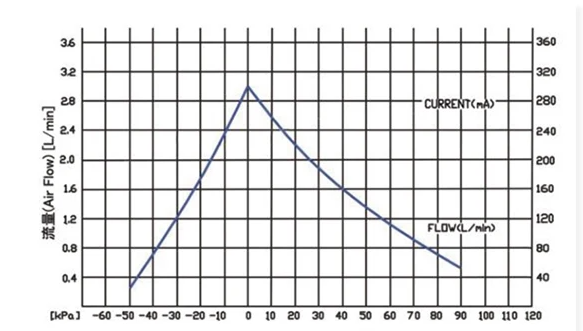

| Voltage | dc6v 12v | Current | 900mA |

| Power | 11W | Pressure | -80kpa |

| Media | Air | Life cycle | 800 hours |

| Flow | 11LPM | Noise | 75dB |

How to improve the pumping efficiency of micro piston vacuum pump?

1. Optimized design: Optimize the structure of the micro piston pump to improve the matching accuracy of the pump chamber and piston, reduce friction and resistance, and improve volumetric efficiency and flow channel efficiency.

2. Choose a high-efficiency motor: Choose a high-efficiency, high-torque motor to ensure the stability and continuity of the piston's reciprocating motion and improve mechanical efficiency.

3. Reduce leakage: Optimize the sealing structure and materials to reduce leakage between the piston and the pump chamber and improve sealing performance.

4. Reduce resistance: Optimize the design of the flow channels of the air inlet and outlet to reduce the flow resistance of gas and improve the efficiency of air intake and exhaust.

5. Constant pressure control: Use a constant pressure control system to keep the outlet pressure of the micro piston pump constant and improve the pumping efficiency.

6. Regular maintenance: Regular maintenance and maintenance of the Vacuum Sealer Piston Pump, cleaning the pump cavity and replacing seals and other measures can restore its performance and improve the pumping efficiency.

7. Control the working temperature: Lowering the working temperature of the micro piston pump can reduce heat loss and friction resistance and improve pumping efficiency.

How to measure the vacuum degree of micro piston pump?

1. Vacuum pressure gauge measurement method: Use a vacuum pressure gauge to directly measure the vacuum degree of the micro piston pump. Connect the pressure gauge to the outlet pipe of the micro piston pump, start the pump and adjust the opening of the outlet valve so that the pump runs under the required working conditions. Observe the reading of the pressure gauge to obtain the vacuum degree of the micro piston pump.

2. Gas flow measurement method: By measuring the gas flow delivered by the micro piston pump, the vacuum degree of the pump can be calculated indirectly. This method requires the use of a gas flow meter and related measuring instruments, and also needs to consider the influence of factors such as gas temperature, pressure, and humidity on the measurement results.

3. Ultimate pressure measurement method: Evaluate the vacuum degree of the piston type pump by measuring its ultimate pressure. Instruments such as resistance vacuum gauges or capacitance vacuum gauges are usually used to measure the ultimate pressure of the pump. These instruments can directly read the vacuum degree value of the pump.

4. Comparative measurement method: Compare the micro piston pump with a standard pump or vacuum system with a known vacuum degree, and evaluate the vacuum degree of the micro piston pump by comparing the performance indicators of the two. This method requires the use of a standard pump or vacuum system as a reference, and the consistency of the working conditions and working conditions of the two needs to be considered.

How does the vacuum degree of the micro piston pump affect the pumping effect of the vacuum packaging machine?

The vacuum degree of the 12V Mini Diaphragm Vacuum Pump has a significant impact on the air extraction effect of the vacuum packaging machine. First of all, the higher the vacuum degree of the Mini Air Vacuum Pump, the stronger its pumping capacity. The high vacuum micro piston pump can extract the air in the package faster, shorten the extraction time and improve production efficiency. This means that under the same conditions, a high-vacuum micro-piston pump can pump out the gas in the package faster, thereby completing the pumping process faster.

Secondly, high vacuum micro piston pumps can better adapt to various packaging materials and thicknesses. Since different packaging materials and thicknesses have different requirements for the air pumping process, high vacuum micro piston pumps can better adapt to these differences and reduce problems such as bag bulging and bag breakage caused by insufficient or uneven air pumping. This helps improve packaging quality and product aesthetics while maintaining product freshness and taste.