DC12V vacuum sealer piston pump

$5.671000-9999 Piece/Pieces

$3.83≥10000Piece/Pieces

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,EXW,FCA,DDU,DDP,CIF,Express Delivery |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

$5.671000-9999 Piece/Pieces

$3.83≥10000Piece/Pieces

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,EXW,FCA,DDU,DDP,CIF,Express Delivery |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

Model No.: DHB-ZK65

Brand: Deyuxin

Apply: Mainly for middle and high-end dispenser ,aquarium equipment, and household appliances, and other products.

Media: Air

Environment: 5℃ ~55℃

Max Vacuum Pressure: <-75Kpa

Rated Voltage: DC12.0 V

Life Test: >50,000 cycles (work for 10sec and stop for 5sec as a cycle )

Non-load Current: <900 mA

NW: 130g

Custom: Available

Noise: <70db

What is the role of a Mini piston pump in a vacuum sealing machine?

The role of the Piston Pump in the vacuum sealing machine is to provide a stable and continuous air flow to extract the air from the packaging bag and achieve the effect of sealing the mouth. Specifically, the piston pump pumps air

It generates negative pressure, extracts the air from the packaging bag, forms a vacuum state at the sealing area, and seals the mouth at the same time. This can effectively prevent external air from entering the packaging bag and prolong the food delivery time.

The shelf life and storage time of other items.

In addition, the DC Piston pump can also play a role in regulating pressure and flow in the vacuum sealing machine. By adjusting the working pressure and flow rate of the piston pump, the tightness and sealing effect of the seal can be controlled.

Fruit to meet the needs of different packaging materials and sealing requirements.

How does a Piston Type Vacuum Pump gradually pump out high-pressure gas?

The piston pump realizes the gradual extraction of high-pressure gas through the reciprocating motion of the piston. Specifically, when the piston reciprocates, the volume in the pump body changes, forming a low-pressure or high-pressure area. When the piston moves to one side, the volume in the pump body increases, forming a low pressure. At this time, the suction port opens and external air is sucked into the pump body; when the piston moves to the other side, the volume in the pump body decreases, forming a high pressure. At this time, the exhaust The air port opens and the internal gas is discharged. Through the continuous reciprocating motion of the piston, the piston pump can continuously and gradually pump out high-pressure gas.

In addition, in order to achieve better pumping effect, piston Mini Pumps usually adopt multi-stage compression. That is, through the series or parallel connection of multi-stage pistons, the gas is compressed step by step, and finally reaches the required high pressure.

pressure. This multi-stage compression method can improve extraction efficiency, reduce power consumption and temperature rise, and reduce the gas compression ratio.

In short, the piston pump realizes the gradual extraction of high-pressure gas through the reciprocating motion of the piston and multi-stage compression, and can provide a stable and continuous air flow.

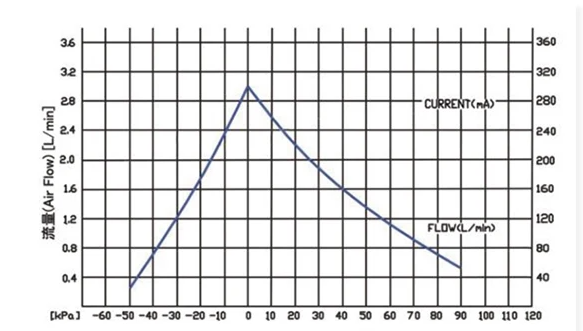

Technical Specification

| Voltage | dc6v 12v | Current | 900mA |

| Power | 11W | Pressure | -80kpa |

| Media | Air | Life cycle | 800 hours |

| Flow | 11LPM | Noise | 75dB |

How does a Diaphragm Piston Pump achieve multi-stage compression?

The Mini Piston Vacuum Pump realizes multi-stage compression mainly in two ways: series connection and parallel connection. In series mode, multiple pistons are connected in sequence, with the output of the previous stage connected to the input of the next stage, and so on. In this way, the output gas of the previous stage can be compressed to a higher pressure and then passed to the next stage for further compression. In the parallel mode, multiple pistons work at the same time, each piston can compress the gas, and then bring the gas together to finally achieve the required compression ratio and flow rate.

The main advantages of multi-stage compression are that it can improve compression efficiency, reduce power consumption and temperature rise, and reduce the compression ratio of gas. In multi-stage compression, the size and stroke of the pistons at each stage are usually gradually reduced to accommodate different levels of compression needs. This design can reduce the force on the single-stage piston and extend the service life of the equipment.

However, multi-level compression also has some disadvantages. First of all, multi-stage compression requires adding multiple levels of compression systems and adding supporting equipment such as coolers and intercooling systems to each level, which will increase the manufacturing cost and operation and maintenance cost of the equipment. Secondly, the installation of multi-stage compression requires high technical requirements, especially for larger-capacity compressors. The installation needs to take into account various factors such as process piping and control system linkage, making installation difficult.

What are the most popular designs of piston pumps?

1. High efficiency: In order to meet the growing requirements for energy efficiency, the design of piston pumps is developing towards high efficiency. This means that the mechanical friction and leakage of the mini piston air pump should be minimized to improve energy efficiency and reduce unnecessary energy loss.

2. Compactification: With the advancement of technology, piston pumps are getting smaller and smaller, making them more suitable for space-constrained applications. The compact design also contributes to the piston pump's maneuverability, making it more flexible for a variety of application needs.

3. Long life: The reliability of piston pumps is crucial, so designers are looking to extend the service life of piston pumps. This is often achieved through the selection of high-quality materials, meticulous workmanship and effective maintenance strategies.

4. Intelligentization: With the development of the Internet of Things and sensor technology, the design of piston pumps is also developing in the direction of intelligence. By integrating sensors and control systems, piston pumps can achieve functions such as remote monitoring, fault diagnosis, and automatic adjustment, thereby improving their operating efficiency and reliability.

5. Modular design: Modular design helps simplify the manufacturing process of piston pumps, reduce production costs, and improve its maintainability and repairability. By designing different parts of the pump (such as cylinder, piston and valve) into independent modules, they can be easily replaced and repaired, thus extending the service life of the piston pump.

6. Environmental awareness: With the increasing emphasis on environmental protection, the design of piston pumps also pays more attention to environmental protection. This includes selecting materials and designs that are low-wear, low-leakage and low-noise, as well as optimizing the hydrodynamic performance of the pump to reduce energy consumption and emissions.

How long do piston pumps last?

The service life of a Vacuum Sealer Piston Pump depends on many factors, such as pump type, manufacturing quality, operating environment, maintenance, etc. Generally speaking, the design life of a piston pump can range from a few hours to several

Years vary depending on its usage and operating conditions. In order to extend the service life of the piston pump, you need to pay attention to the following points:

1. Correct installation and maintenance: Correct installation and use of the piston air vacuum pump according to the instructions provided by the manufacturer, regular maintenance and repair, and replacement of worn parts can extend the service life of the pump.

2. Good lubrication: Ensure that the bearings and seals of the piston pump are fully lubricated to reduce friction and wear.

3. Control operating parameters: During operation, control the operating parameters of the piston pump, such as pressure, flow, temperature, etc., to keep them within a reasonable range to avoid overload operation.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.