high pressure piston air pump

$5.51000-9999 Piece/Pieces

$3.8≥10000Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,EXW,DDU,DDP,CIF,Express Delivery,CFR |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

$5.51000-9999 Piece/Pieces

$3.8≥10000Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,EXW,DDU,DDP,CIF,Express Delivery,CFR |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

Model No.: DHB-ZK65

Working Temperature: 5℃ ~55℃

Service: Customized OEM

Noise Level: <75b

Life Test: >50, 000 cycles

Media: Air

N.W.: 130g

Rated Voltage: DC12V

Maximum Pressure: >200Kpa

Current: <900mA

| Selling Units | : | Piece/Pieces |

| Package Type | : | Export carton |

Which is better, Piston Pump or gear pump?

Piston pumps and gear pumps each have their own advantages and disadvantages. Which one is better depends on the actual application scenario and needs.

The main advantages of piston Mini Pumps include large flow rates and precise displacement. Piston pumps can achieve large flow rates and are suitable for transporting and compressing large amounts of liquid or gas. In addition, when the Piston Type Vacuum Pump is working, each reciprocating movement of the piston will accurately deliver a precise amount of proportionally controlled liquid or gas. However, piston pumps also have some disadvantages, such as large energy consumption, because the reciprocating motion of the piston pump requires a large amount of energy, so the amount of liquid or gas transported cannot be too large in a short period of time. Additionally, piston pumps have higher maintenance costs because of their mechanical complexity.

The advantages of gear pumps include small size, simple structure, low oil cleaning requirements, and low price. This kind of pump is suitable for occasions where flow and pressure requirements are not high. However, gear pumps also have some disadvantages. For example, the pump shaft is subject to unbalanced force, severe wear and tear, and large leakage.

What are the main factors that determine the efficiency difference between piston pumps and gear pumps?

The efficiency difference between piston pumps and gear pumps mainly comes from the following aspects:

1. Working principle: The working principle of a Mini piston pump is to transport fluid through the reciprocating motion of the piston in the cylinder. This process involves friction and energy loss. In contrast, the working principle of a gear pump is to transport fluid through the meshing of gears. Its structure is relatively simple and its friction loss is small.

2. Fluid characteristics: Piston pumps are suitable for transporting fluids with higher viscosity. For low-viscosity fluids, the efficiency of the piston pump may decrease. Gear pumps are suitable for a variety of fluids, including low-viscosity gases and liquids.

3. Mechanical loss: Due to the large friction between the piston and the cylinder in the DC Piston pump, large mechanical losses will occur, thereby reducing efficiency. The gear friction in the gear pump is relatively small, the mechanical loss is small, and the efficiency is high.

4. Design factors: The design of piston pumps and gear pumps will also affect their efficiency. For example, the pistons of piston pumps and the gears of gear pumps require precise manufacturing and installation to ensure sealing and reduce friction. If not designed properly or manufactured with insufficient precision, efficiency may suffer.

Technical Specification

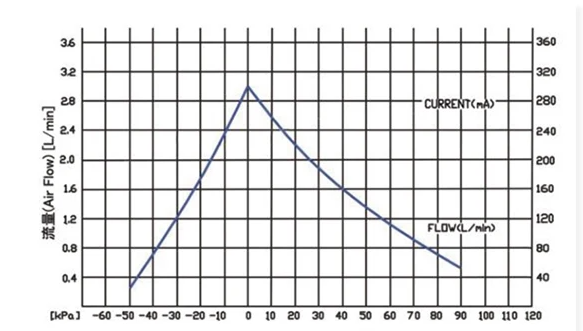

| Voltage | dc6v 12v | Current | 900mA |

| Power | 11W | Pressure | -80kpa |

| Media | Air | Life cycle | 800 hours |

| Flow | 11LPM | Noise | 75dB |

The efficiency difference between piston pumps and gear pumps mainly comes from the following aspects:

1. Working principle: The working principle of a Mini Piston Vacuum Pump is to transport fluid through the reciprocating motion of the piston in the cylinder. This process involves friction and energy loss. In contrast, the working principle of a gear pump is to transport fluid through the meshing of gears. Its structure is relatively simple and its friction loss is small.

2. Fluid characteristics: Piston pumps are suitable for transporting fluids with higher viscosity. For low-viscosity fluids, the efficiency of the piston pump may decrease. Gear pumps are suitable for a variety of fluids, including low-viscosity gases and liquids.

3. Mechanical loss: Due to the large friction between the piston and the cylinder in the piston air vacuum pump, large mechanical losses will occur, thereby reducing efficiency. The gear friction in the gear pump is relatively small, the mechanical loss is small, and the efficiency is high.

4. Design factors: The design of piston pumps and gear pumps will also affect their efficiency. For example, the pistons of piston pumps and the gears of gear pumps require precise manufacturing and installation to ensure sealing and reduce friction. If not designed properly or manufactured with insufficient precision, efficiency may suffer.

What are the advantages and disadvantages of piston pumps and gear pumps?

The advantages of piston pumps include large flow rate, precise displacement, strong self-priming force, and insensitivity to oil contamination. Piston pumps are suitable for transporting and compressing large amounts of liquid or gas, and can accurately control the flow and displacement of liquid or gas. In addition, the vauum piston pump also has the advantages of simple structure, small size, light weight, good craftsmanship, cheap price, large speed range, ability to withstand impact loads, easy maintenance and reliable operation. However, piston pumps also have some shortcomings, such as unbalanced radial force, large flow pulsation, loud noise, low efficiency, poor interchangeability of parts, difficulty in repairing after wear, and cannot be used as a variable displacement pump.

The main advantages of gear pumps include simple and compact structure, small size, light weight, good craftsmanship, cheap price, strong self-priming force and insensitivity to oil contamination. Gear pumps are suitable for occasions with low flow and pressure requirements and can meet the needs of high lift and high flow conditions. They have been widely used in petrochemical, chemical, electric power, construction, fire protection and other industries. However, gear pumps also have some shortcomings, such as unbalanced radial force, large flow pulsation, loud noise, and low efficiency.

How is the efficiency of a Mini Piston Air Pump evaluated?

The efficiency of a piston pump can be evaluated by:

1. Laboratory test: Test the piston pump in the laboratory, and calculate the efficiency of the piston pump by measuring input power, flow, pressure and other parameters. This method can provide more accurate data, but it requires certain testing equipment and time.

2. On-site testing: Test the piston pump on site, measure input power, flow, pressure and other parameters in actual operation, and calculate the efficiency of the piston pump. This method needs to consider interference factors in the on-site environment, such as pipeline vibration, power supply fluctuations, etc., but it can more truly reflect the efficiency of the piston pump in actual use.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.