Vacuum Blender DC Piston Vacuum Pump

$5.831000-9999 Piece/Pieces

$3.87≥10000Piece/Pieces

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,EXW,FCA,DDU,DDP,CIF,Express Delivery |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

$5.831000-9999 Piece/Pieces

$3.87≥10000Piece/Pieces

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,EXW,FCA,DDU,DDP,CIF,Express Delivery |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

Model No.: DHB-ZK12

Brand: Deyuxin

MOQ: 1000PCS

Temp: 5℃~55℃

Media: Air

Power: 11W

Life Test: >800Hours

Rated Voltage: DC12.0V

N.W: 300g

Pressure: <-80Kpa

DC12.0 V /24.0 V Piston Pump DHB-ZK12 belongs to Mini Diaphragm Pump.This piston pump is widely used for household appliance,massage,medical equipment products etc.

How does the Mini Piston Air Pump work?

The Vacuum Piston Pump is driven by a DC motor, which causes the diaphragm inside the pump to reciprocate, thereby generating a pressure difference at the pump port to realize liquid transportation. This type of pump is characterized by its small size and can be used in applications that require less space. Micro DC piston pumps have a wide range of applications in pumping air or water and can be adjusted according to different needs. At the same time, in order to ensure the safety and stability of the micro DC Piston pump, regular maintenance and upkeep is required.

What is the specific operation of the Diaphragm Piston Pump in the wall breaking machine?

The specific operation process of the micro DC piston pump in the wall breaking machine is as follows:

1. When the wall breaking machine is powered on, the Mini Piston Vacuum Pump starts to work. The piston reciprocates in the pump cylinder, generating a certain amount of pressure and suction.

2. The reciprocating motion of the piston is transmitted to the tool through the connecting rod, causing the tool to rotate. At the same time, the pressure and suction generated by the piston act on the cutter to cut the food into fine particles.

3. There are multiple sensors and safety protection devices inside the wall breaking machine to ensure the normal operation and safety of the piston pump. For example, when there are too many ingredients or too hard ingredients in the wall-breaking machine, the wall-breaking machine will automatically adjust the speed and power of the piston pump to adapt to different ingredients.

4. During the crushing and mixing process, the wall breaker is equipped with filters, silencers and other devices to filter and reduce noise in the medium in the conveying pipeline. This can extend the service life of the wall breaker and reduce the impact of noise on users.

5. The wall breaking machine usually has an automatic cleaning function, in which the vacuum blender piston pump plays a certain role. Through the reciprocating motion of the piston, the remaining food and dirt in the pipeline can be cleaned to ensure the hygiene and cleanliness of the wall breaking machine.

Does the Piston Type Vacuum Pump have flow?

Yes, piston pumps have flow. The flow rate of a piston pump refers to the amount of liquid delivered by the pump per unit time, usually expressed by volume.

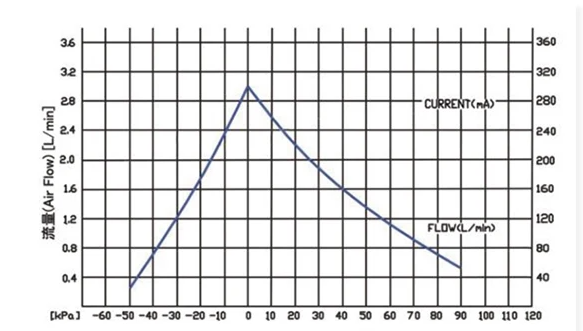

The calculation formula for the flow rate of a piston pump is: Q=nxq, where Q represents the flow rate of the pump, n represents the number of reciprocations of the piston, and q represents the displacement of each reciprocation of the piston. Therefore, the flow rate of the piston pump is affected by the number of reciprocations of the piston and the displacement of each reciprocation.

What types of piston pumps are there?

1. Pneumatic plunger pump: Through pneumatic transmission, the reciprocating motion of the plunger is converted into the pressure energy of the liquid. It is suitable for high-pressure, large-flow, and high-power situations.

2. Electric plunger pump: Driven by a motor, the rotational motion is converted into reciprocating motion of the plunger, thereby generating pressure. This pump is compact, easy to maintain, and suitable for various industrial fields.

3. Hydraulic plunger pump: Through hydraulic transmission, the rotational motion is converted into the reciprocating motion of the plunger, thereby generating pressure. This kind of pump has high efficiency and stable pressure, and is suitable for high-precision and high-pressure situations.

4. Micro pneumatic diaphragm pump: driven by air pressure, the liquid is transported through the reciprocating motion of the diaphragm. This kind of pump has a simple structure, low price and easy portability, and is suitable for use in laboratories, small industrial equipment and other fields.

5. Micro Electric Diaphragm Pump: driven by a motor, the rotational motion is converted into the reciprocating motion of the diaphragm, thereby generating pressure. This kind of pump has adjustable flow rate and is easy to control, making it suitable for various industrial fields.

What are the advantages and disadvantages of micro piston pumps?

The advantages of micro piston pumps mainly include:

1. High pressure: Because the piston reciprocates in the cylinder, it can generate high pressure, which can meet the transportation needs of high pressure and high flow.

2. Adjustable flow: By adjusting the number of reciprocations of the piston or changing the stroke of the piston, the flow of the micro piston pump can be adjusted to achieve precise control.

3. Long life: Because the friction between the piston and the cylinder is small and made of high-quality materials, the diaphragm piston pump has a long service life.

4. High reliability: The vacuum piston pump has a simple and compact structure, is not prone to failure, is easy to maintain, and has high reliability.

However, micro piston pumps also have some disadvantages:

1. Louder noise: Larger noise will be generated during the gas compression and release process inside the micro piston pump.

2. High requirements on the medium: Micro piston pumps are suitable for transporting clean, particle-free media. If the medium contains impurities or particles, it may affect the performance and service life of the pump.

3. Higher cost: Micro piston pumps are usually made of high-quality materials, so their costs are high and they are not suitable for large-scale applications.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.