Best Mini Plastic Submersible Water Pump

$55-4999 Piece/Pieces

$4.5≥5000Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | EXW,FOB,CIF |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shekou,Yantian |

$55-4999 Piece/Pieces

$4.5≥5000Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | EXW,FOB,CIF |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shekou,Yantian |

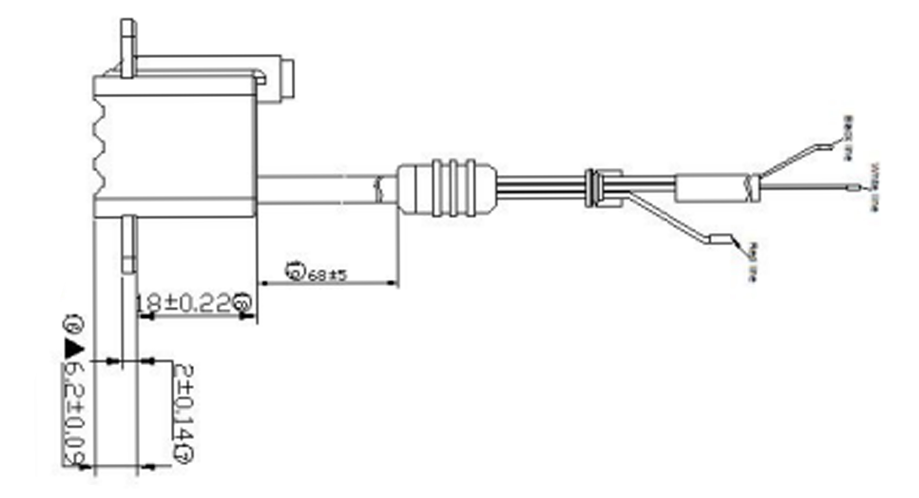

Model No.: DQB421-SB-2

Keywords: Best Submersible Pump

Rated Voltage: 18V

Current: <50mA

Working Temperature: 5℃~55℃

Power: 0.9W

Flow: 15500mL/H

Media: Water

Life Test: 20000 cycles

Noise: 40dB

OEM,ODM: Support

| Selling Units | : | Piece/Pieces |

What factors affect the head of a Micro Submersible Pump?

Water pump pipeline problem: Excessive bends, valves, or other flow resistances in the pipeline can slow down the flow of water, thereby affecting the head of the water pump. Optimizing pipeline design, reducing unnecessary bends and valves, can increase head.

Water pump speed issue: The speed of the water pump directly affects its head. When the speed of the water pump is too low, the volume of water conveyed decreases, resulting in a low head. Therefore, ensuring that the water pump operates at an appropriate speed is the key to maintaining high head.

Water pump impeller problem: Wear or damage to the impeller can significantly affect the head of the water pump. Worn impellers can lead to reduced efficiency and may even fail to function properly. Regular inspection and replacement of worn impellers can maintain the efficient operation of the water pump.

Terrain height difference: Terrain height difference is one of the key factors affecting the head of submersible pumps. The water pump not only needs to overcome the height difference from its location to the water level at the outlet, but also needs to overcome the height difference from its location to the water level at the pump station.

Liquid flow rate: Liquid flow rate refers to the amount of liquid required to be pumped by the pumping station. The larger the flow, the greater the head that needs to be overcome.

Water pump efficiency: The efficiency of a water pump refers to the power consumption per unit time required for pumping at a pumping station. The higher the efficiency, the smaller the head that needs to be overcome.

Conveying medium: The conveyed medium also has an impact on the head of the water pump. For example, when conveying liquids with high viscosity, the head that needs to be overcome will be much larger than when conveying clean liquids.

How to improve the head of a Mini Submersible Pump by optimizing pipeline design?

Reducing bends and valves: Bends and valves in pipelines increase fluid resistance, thereby reducing head. Therefore, in pipeline design, unnecessary elbows and valves should be minimized as much as possible, especially in critical areas near pumps.

Optimize pipeline diameter: The diameter of the pipeline also affects the flow rate and flow rate of the fluid. The appropriate pipeline diameter should be selected based on the flow rate and head requirements of the Submersible Pump to ensure smooth flow of fluid in the pipeline.

Avoid excessively long pipelines: Excessive pipelines not only increase fluid resistance, but may also lead to energy loss. Therefore, in design, the length of the pipeline should be minimized as much as possible, especially in high-pressure and long-distance transportation situations.

Use smooth inner wall pipelines: The inner wall of the pipeline should be as smooth as possible to reduce friction between the fluid and the pipeline wall and reduce energy loss.

Reasonable layout of pipelines: The layout of pipelines should be reasonable, avoiding sharp turns and sudden changes in direction, in order to reduce turbulence and eddy currents in the pipeline.

Consider using elastic joints and shock absorbers: Using elastic joints and shock absorbers at pipeline connections can reduce pipeline vibration and impact, improve pipeline stability and fluid transport efficiency.

What are the effects of a high or low head of a Small Submersible Pump?

When the head is too high, the DC Submersible Pump needs to withstand greater pressure and load, which may lead to increased wear of the internal components of the pump, thereby shortening its service life. At the same time, excessive head may also reduce the efficiency of submersible pumps, as the pump needs to consume more energy to overcome greater resistance. In addition, a high head may also cause safety hazards, such as pipeline rupture, motor overheating, and other issues.

On the contrary, when the head is too low, the submersible pump may not be able to meet the actual usage needs. For example, in situations where a large water flow rate or high water level difference is required, a submersible pump with a low head may not be able to deliver water to the designated location, resulting in poor working efficiency. In addition, long-term operation under low head conditions may also cause damage to the motor and bearings of the submersible pump due to insufficient load.

How to determine whether the head of a Miniature Submersible Pump is appropriate?

Understand the requirements and environment: Firstly, clarify the specific requirements for using submersible pumps, such as the amount of water to be transported, the distance to be transported, and the height of the destination. At the same time, environmental factors such as the depth and quality of the water source should also be considered.

Refer to product instructions: Refer to the product manual of the selected micro submersible pump to understand key information such as the pump's head range and performance curve. This will help you understand the theoretical head and possible maximum head of the pump.

Actual testing:

Pressure testing method: Close all outlet pipelines, start the submersible pump, and use a pressure gauge to measure the water pressure at the position where the pump outlet is connected to the outlet pipeline. Compare the measured water pressure with the corresponding standard head value in the product description. If the difference is small, it indicates that the water pump has reached the standard head.

Flow comparison method: Determine the flow rate of the outlet pipeline, and then calculate the actual required flow rate based on the performance curve of the submersible pump and the required standard head value. Then open all outlet pipes, measure the actual flow rate output by the submersible pump, and compare it with the required flow rate. If the difference is small, the head is appropriate.

Observing the operation status: In actual use, observe the operation status of the submersible pump. If there is no abnormal noise, overheating, or vibration during the operation of the pump and it can meet the usage requirements, then its head can be considered appropriate.

Technical Specification

| Voltage | DC18V | Current | 50mA |

| Static water head pressure | 55±10CM | Operating flow rate@waterhead pressure 15CM | 28000~34000 mL/h |

| Output power consumption | 0.13W | Operating Noise | <40dB |

How to determine the head of a electric submersible pump based on pressure testing method?

Prepare testing tools: First, you need to prepare a pressure gauge. This pressure gauge should have good accuracy and range to meet the needs of testing. At the same time, ensure that the submersible pump and its related pipelines are in normal working condition, without any leakage or blockage issues.

Install pressure gauge: Connect the pressure gauge to the outlet of the submersible pump. Ensure that the connection is secure and avoid leakage or detachment during the testing process.

Start the 1.5 inch submersible pump: After ensuring that the power supply and control system are functioning properly, start the submersible pump. Let it run for a period of time, and then proceed with the subsequent testing steps after it stabilizes.

Record pressure data: After the submersible pump operates stably, observe and record the data on the pressure gauge. These data represent the outlet pressure of the submersible pump under specific operating conditions.

Comparison performance curve: Refer to the product manual or relevant information of the submersible pump to find its performance curve. On the performance curve, you can find the corresponding outlet pressure values for different lift levels.

Determine head: Compare the actual outlet pressure value obtained from testing with the data on the performance curve. Find the head value closest to the test pressure value, which is the actual head of the submersible pump under the current operating conditions.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.