2 inch electric submersible water pump

$5≥4Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | EXW,FOB,CIF |

| Min. Order: | 4 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shekou,Yantian |

$5≥4Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | EXW,FOB,CIF |

| Min. Order: | 4 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shekou,Yantian |

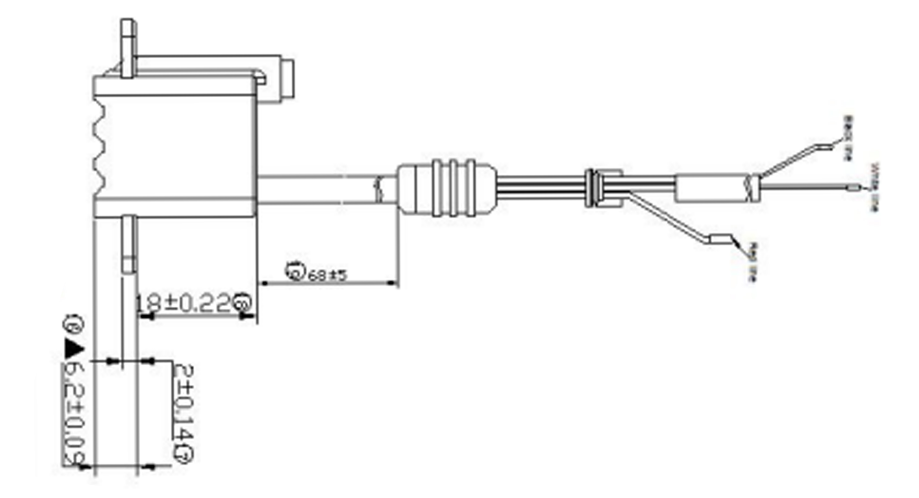

Model No.: DQ421-SB-3

Keywords: submersible electric pump

Rated Voltage: 18V

Current: <50mA

Working Temperature: 5℃~55℃

Power: 0.9W

Flow: 15500mL/H

Media: Water

Life Test: 20000 cycles

Nose: 40dB

OEM,ODM: Support

| Selling Units | : | Piece/Pieces |

How long can a 1 horsepower Micro Submersible Pump run continuously?

The continuous operation time of a micro Submersible Pump depends on multiple factors, including pump design, manufacturing quality, operating environment, liquid properties, and load conditions. Horsepower (hp) is a unit of measurement for pump power, which determines the pump's ability to extract liquid within a certain period of time. However, horsepower itself does not directly determine the duration of continuous operation of submersible pumps.

Usually, submersible pumps can be designed for continuous or intermittent operation. The submersible pump with continuous working system can operate continuously for a long time and is suitable for situations that require continuous pumping. The submersible pump with intermittent working system is designed to stop and rest after running for a certain period of time to avoid overheating or damage.

For a 1 horsepower micro submersible pump, its continuous operating time depends on the specific pump model and design. Generally speaking, micro submersible pumps can operate continuously for several hours to tens of hours, but the specific time should be found in the product manual or manufacturer's recommendations. Meanwhile, the following points should also be noted:

1. Ensure that the submersible pump is installed at the appropriate depth and follow the manufacturer's recommendations for installation and use.

2. Regularly inspect and replace the filters and seals of the submersible pump to ensure its normal operation and extend its service life.

3. Avoid operating the submersible pump for a long time in a liquid containing a large amount of impurities or solid particles, in order to avoid damaging the pump body or reducing efficiency.

When using submersible pumps, attention should be paid to power and electrical safety to avoid dangerous situations such as electric shock or short circuits.

How to calculate the flow rate and head of a micro submersible pump?

The flow rate and head of a micro submersible pump are two important parameters to consider when selecting a submersible pump. The calculation formula for flow rate is: flow rate

(Q) =cross-sectional area of pipeline (A) x flow velocity (V). Among them, the cross-sectional area (A) of the pipeline can be calculated based on the diameter of the pipeline (D), that is, A=π x (D/2) ^ 2, and the flow rate (V) is generally determined based on experience or actual measurement. It should be noted that the flow rate calculated here is the liquid flow rate per unit time, usually measured in cubic meters per hour (m/h) or liters per second (L/s). The calculation formula for head is: head (H)=vertical height (h)+loss along the way (△ h). Among them, the vertical height (h) refers to the vertical distance between the liquid from the outlet of the submersible pump and the target height. Along the way loss (△ h) refers to the loss caused by friction, bending, and other factors when liquid flows in a pipeline. It can be calculated based on factors such as pipeline length, diameter, and fluid properties. It should be noted that the unit of head is usually meters (m), which represents the height at which the liquid is lifted.

In practical applications, it is necessary to choose appropriate submersible pump models and parameters based on specific pumping requirements and liquid properties. Generally speaking

It is said that the selection of flow rate and head needs to meet the pumping requirements, while considering factors such as pipeline length, diameter, and flow rate that affect flow rate and head

The influence of Cheng. In addition, it is also necessary to pay attention to the installation and use methods of submersible pumps to ensure their normal operation and safe use.

Which is better, self priming pump or micro submersible pump?

Micro self suction pumps and micro submersible pumps each have their own characteristics and advantages, and the choice of which one is better mainly depends on your specific needs and usage scenarios.

The advantage of a micro self priming water pump is that it has a self priming function, which can easily transport liquids to the desired location. It is suitable for transporting low viscosity liquids, such as clean water, sewage, etc. It is easy to install and does not require additional water pipes. It can be used as a regular centrifugal pump. However, its self suction height is limited, generally not exceeding 6 meters, and its applicability is limited, making it unsuitable for conveying high viscosity liquids and liquids with high solid particle content.

The micro submersible pump adopts advanced technology design and has the characteristics of high efficiency and energy conservation, which can quickly and effectively complete the tasks of water extraction and discharge. It usually has a high head and can effectively raise the height of water. It is suitable for situations that require long-distance water transportation. It can work in water without the need for a diversion pipe, and has a wide range of applications. It can be used in various scenarios such as drainage, irrigation, and sewage treatment.

Do micro submersible pumps have to be submerged in water?

A micro DC Submersible Pump does not necessarily have to be completely submerged in water, it can only be submerged halfway, but completely submerged does not help the submersible pump dissipate heat.

Submersible pumps are a common type of water pump in the water supply and drainage industry, mainly because they can work by being submerged in water for a long time

And named it a submersible pump. In many special environments, compared to ground pumps, it has stronger applicability and can complete the tasks that ground pumps cannot

Completed homework.

Technical Specification

| Voltage | DC18V | Current | 50mA |

| Static water head pressure | 55±10CM | Operating flow rate@waterhead pressure 15CM | 28000~34000 mL/h |

| Output power consumption | 0.13W | Operating Noise | <40dB |

How to improve the water pressure of micro submersible pumps?

There are several methods to improve the water pressure of micro submersible pumps:

1. Adjust the flow rate of the pump: Reduce the flow rate of the water pump by adjusting the valve or changing the pump speed, thereby reducing the outlet pressure. For micro submersible pumps, the flow rate can be reduced and the water pressure can be increased by adjusting the opening of the outlet valve.

2. Install pressure reducing valve: Install a pressure reducing valve on the pipeline to reduce the high-pressure water pressure to an appropriate level. This can help increase the water pressure of the micro submersible pump and ensure the stability of the outlet pressure.

3. Check the components of the pump: Check the various components of the submersible pump, such as impeller, bearings, and seals, to ensure that they are all in normal working condition. If any worn or damaged parts are found, they should be replaced in a timely manner to ensure that the submersible pump can operate efficiently and increase water pressure.

4. Reduce the installation depth of the pump: If the installation depth of the submersible pump is too deep, it will increase the load on the pump, leading to a decrease in water pressure. Therefore, the installation depth of the submersible pump can be adjusted appropriately to increase water pressure.

5. Clean the water pump inlet: If the water pump inlet is blocked, it will affect the water flow into the pump, causing a decrease in water pressure. Therefore, regularly cleaning the debris and dirt at the inlet of the water pump can ensure smooth water flow and increase water pressure.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.