Normally close one-way solenoid valve for breast pump

$1.51000-9999 Piece/Pieces

$0.7≥10000Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,EXW,DDU,DDP,CIF,Express Delivery |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

$1.51000-9999 Piece/Pieces

$0.7≥10000Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,EXW,DDU,DDP,CIF,Express Delivery |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

Model No.: DQF1-6B-1

Brand: DYX

Types Of: Air Valves &Amp; Vents, Vacuum Relief Valves, Solenoid Valves, Vent Valves, Pressure Reducing Control Valves

Certification: Reach

Support Customization: Oem, Odm

Place Of Origin: China

Application: General

Medium Temperature: High Temperature, Low Temperature, Medium Temperature, Normal Temperature

Power: Solenoid, Electric

Flow Medium: Gas

Structure: Control, Check, Pressure Reducing

Working Temperature: 5℃ ~55℃

Service: Customized OEM

Media: Air

Life Test: >200,000 cycles

Current: <360mA

Pressure: -350mmHg-0

Rated Voltage: DC3.7V 5.0V 12.0V

Power: 1.9-2.5W

N.W.: 17g

Exhaust Speed: <3s( with a 100cc tank, exhaust air from -280mmHg to 15mmHg)

What is a normally closed Solenoid Valve ?

A normally closed pneumatic valve is a normally closed pneumatic valve. Its characteristic is that the valve is usually closed and will only open when a pneumatic signal needs to be input to the valve. Normally closed gas valves are usually used as switches in control systems to control the flow or cutoff of gas. Due to its safety, reliability, simple structure and other advantages, normally closed air valves have been widely used in home automation control systems.In practical applications, a normally closed Mini Solenoid Air Valve usually consists of a valve body, a valve core, a driving mechanism and a spring. When the valve core is not acted upon by external force, it is in a closed state due to the force of the spring. When a pneumatic signal acts on the valve core, the valve core moves against the elastic force of the spring under the force of the pneumatic signal, thereby opening the valve. When the pneumatic signal is removed, the spring will push the valve core back to the closed position.

1. Normally, the air closing valve has various control methods, and can be controlled by solenoid valve, pneumatic valve and other control methods. When selecting a Normally Closed Air Valve, you need to make a selection based on the specific use environment and working conditions, such as gas medium, temperature, pressure, flow and other parameters, as well as the safety, reliability, stability and other requirements of the valve.

How does a normally closed Micro Solenoid Air Valve work in a breast pump?

A normally closed Dc Micro Air Valve plays an important role in the breast pump to control the flow of gas to ensure the normal operation of the breast pump.

When it is time to pump milk, a normally closed micro air valve is closed to prevent air from entering the breast pump. At this time, the negative pressure inside the breast pump will suck the milk from the breast into the breast pump and

Drain through the catheter.

When the breast pump is completed, a normally closed micro air valve opens, allowing air to enter the inside of the breast pump and eliminating the internal negative pressure. This helps prevent milk reflux and ensures it works properly the next time you pump.

How does the mini air control valve in the breast pump ensure stable suction?

The micro valve in the breast pump ensures stable suction by:

1. Air pressure adjustment: When the breast pump starts to work, the micro air valve will open according to the set negative pressure value, allowing external air to enter the inside of the breast pump and form an air pressure balance with the negative pressure generated inside. This ensures stable suction and prevents the suction from being affected by negative pressure that is too large or too small.

2. Automatic closing mechanism: During the sucking process, if the negative pressure of the breast pump reaches a certain value, the air valve will automatically close to prevent excessive negative pressure from causing discomfort or damage to the breasts. This automatic shut-off mechanism ensures that the suction power does not continue to increase and remains stable.

3. Air tightness design: The 3V Electric Solenoid Air Valve itself has good air tightness, which can effectively prevent the infiltration of external air and the leakage of internal air. This ensures that the air pressure inside the breast pump remains stable, thereby ensuring the stability of suction.

4. Material selection: Micro air valves are usually made of pressure-resistant and wear-resistant materials, which can ensure the stability of long-term use. In addition, for different usage environments and usage requirements, the material selection of micro air valves will also be different to ensure the reliability of its performance.

5. Structural design: The structural design of the micro air valve will also affect its stability and reliability. Reasonable design can ensure that the air valve will not get stuck or blocked during operation, thus ensuring the stability of suction.

Technical Specification

| Model | DQF2-6B | Voltage | dc6v 9v 12v |

| Current | 375mA,365mA,360mA | Power | 2.3-2.7W |

| Pressure | 350mmHg | Leakage | 6mmHg/min(with a 500 cc tank,inflate air from 0-280mmHg,then stop for 30 secs |

| Media | Air | Life cycle | more than 200000 cycycles |

How does the mini air release valve control gas flow?

The micro vent valve can control gas flow in the following ways:

1. Adjust the valve opening: Micro vent valves usually have an adjustable valve opening, and the gas flow can be controlled by changing the opening of the valve. When the valve opening increases, the gas flow increases; conversely, the gas flow decreases. This adjustment method can be achieved through manual or automatic control.

2. Change the cross-sectional area of the gas channel: The gas channel of the normally closed air valve usually has a certain cross-sectional area, and the gas flow rate is controlled by changing the cross-sectional area of the channel. When the channel cross-sectional area increases, the gas flow rate increases; conversely, the gas flow rate decreases. This adjustment method is usually achieved by changing the internal structure of the valve.

3. Change the gas pressure: The micro vent valve can be installed on the gas pipeline with a pressure control device to control the gas flow by changing the gas pressure. When the gas pressure increases, the gas flow rate increases; conversely, the gas flow rate decreases. This adjustment method requires the installation of corresponding pressure control devices on the pipeline.

4. Combined control method: In practical applications, the above control methods can be used in combination to achieve more precise and flexible gas flow control. For example, more precise gas flow adjustment can be achieved by adjusting the valve opening and gas channel cross-sectional area, and at the same time, combined with a gas pressure control device, the flow control of the entire gas pipeline can be achieved.

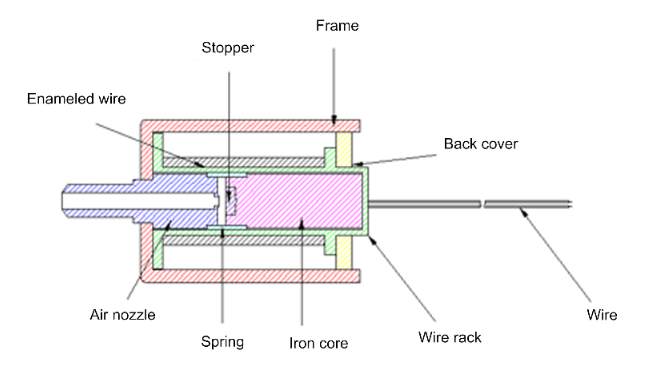

Dimension Structure

How to adjust the negative pressure of the micro valve in the breast pump?

The micro-valve in the breast pump usually achieves negative pressure regulation in the following ways:

1. The Normally Close One-Way Solenoid Valve will open according to the set negative pressure value, allowing external air to enter the inside of the breast pump and form an air pressure balance with the negative pressure generated inside. This can ensure stable suction and provide a comfortable breast pumping experience.

2. Micro air valves usually have good air tightness and can effectively prevent the infiltration of external air and the leakage of internal air. This keeps the air pressure inside the breast pump stable, ensuring consistent suction.

3. The structural design of the micro air valve will also affect its ability to adjust negative pressure. Reasonable design can ensure that the air valve will not get stuck or blocked during operation, thus ensuring the accuracy and stability of adjustment.

4. Some high-end breast pumps may also be equipped with an intelligent control system, which can detect the current negative pressure value or suction force through sensors and automatically adjust the opening degree of the micro-valve to achieve more precise negative pressure regulation.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.