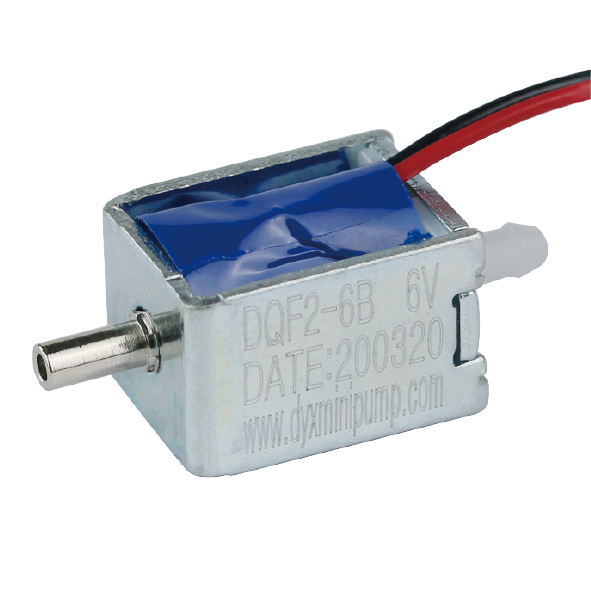

Miniature normally closed Solenoid Valve is a small valve that usually has normally closed characteristics and is mainly used to control the flow of gas or liquid. Due to its compactness, efficiency and reliability, miniature normally closed valves are widely used in many fields, such as precision instruments, fluid control, vacuum systems, etc. This article will discuss the technical issues of miniature normally closed valves, including valve sealing performance, fluid flow resistance, valve opening and closing force and driving method, valve reliability and life etc.

2. Valve sealing performance

Sealing performance is one of the important technical indicators of miniature normally closed valves. The sealing performance of the valve directly affects the accuracy and reliability of fluid control. In order to ensure that the valve has good sealing performance, the following aspects need to be paid attention to:

1. Valve material: Choosing the right material is the key to ensuring the sealing performance of the valve. Commonly used valve materials include metal, plastic, and ceramics. Materials with good corrosion resistance, high temperature resistance, and high pressure resistance need to be selected according to actual needs.

2. Sealing gasket: For miniature normally closed valves that require sealing gaskets, it is necessary to choose gasket materials with good compressibility, resilience and corrosion resistance, such as rubber, graphite, etc. At the same time, ensure that the gasket is installed correctly and tightened evenly to prevent damage or displacement of the gasket.

3. Processing accuracy: The processing accuracy of the Normally Closed Air Valve has a great impact on its sealing performance. The mating surface of the valve seat and valve disc must be smooth and free of burrs, unevenness or damage to ensure that the sealing surface can fit tightly.

4. Temperature and pressure: Valves will encounter various temperature and pressure conditions during use. It is necessary to choose materials and sealing forms that can withstand the corresponding temperatures and pressures to prevent leakage.

Fluid flow resistance

The fluid flow resistance of the miniature normally closed Dc Micro Air Valve is also one of its important technical indicators. The size of fluid flow resistance directly affects the flow rate and pressure loss of fluid through the valve. In order to reduce fluid flow resistance, the following aspects need to be paid attention to:

1. Flow channel design: Flow channel design is a key factor affecting the fluid flow resistance of micro normally closed valves. The flow path should be as smooth and smooth as possible to reduce the resistance when the fluid passes through. At the same time, the appropriate flow channel cross-sectional shape and size should be selected according to actual needs to obtain the best flow performance.

2. Material selection: Material selection will also affect the fluid flow resistance of the miniature normally closed mini air release valve. Choosing materials with good lubrication properties and a low friction coefficient can reduce the resistance of fluid passing through the valve. For example, as metal materials, you can choose materials with good wear resistance and corrosion resistance such as stainless steel or cemented carbide.

3. Processing accuracy: The processing accuracy of the miniature normally closed valve will also affect the fluid flow resistance. Ensure that the roughness, smoothness and geometric accuracy of the flow channel surface meet the requirements, which can reduce the resistance when the fluid passes through. At the same time, avoid burrs, unevenness or damage in the flow channel.

4. Cleanliness: Keeping the interior of the miniature normally closed valve clean is also one of the key measures to reduce fluid flow resistance. During use, the valve must be cleaned regularly to prevent dirt, impurities, etc. from clogging the flow path and affecting the fluid flow performance.

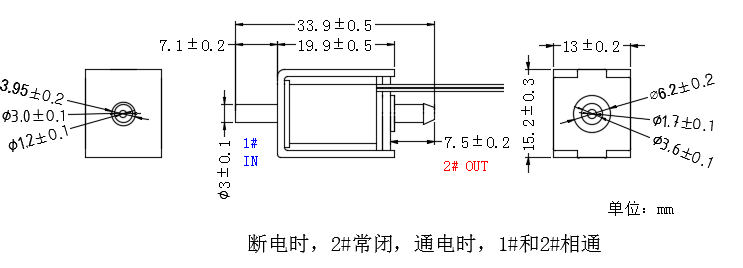

Technical Specification

| Model | DQF2-6B | Voltage | dc6v 9v 12v |

| Current | 375mA,365mA,360mA | Power | 2.3-2.7W |

| Pressure | 350mmHg | Leakage | 6mmHg/min(with a 500 cc tank,inflate air from 0-280mmHg,then stop for 30 secs |

| Media | Air | Life cycle | more than 200000 cycycles |

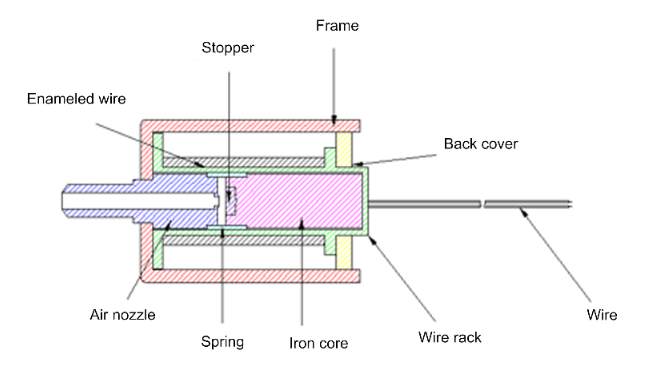

Valve opening and closing force and driving method

Valve opening and closing force and driving mode are also one of the technical issues of miniature normally closed valves. Appropriate driving method can reduce the opening and closing force of the valve and improve the reliability and convenience of valve operation. The following are some factors that affect the valve's opening and closing force and driving method:

1. Valve size and weight: The larger the valve size and the heavier the weight, the greater the opening and closing force required. Therefore, for large or heavy valves, it is necessary to choose a driving method with sufficient driving force and stability, such as electric drive or pneumatic drive.

2. Sealing pressure and spring force: Valve sealing pressure and spring force are also one of the factors that affect the opening and closing force. Valves used under high pressure or vacuum conditions require greater sealing pressure, so it is necessary to select a driving method with sufficient thrust or strengthen the elastic force of the spring.

3. Operating frequency and reliability: For miniature normally closed valves that require frequent operations, a driving method with a higher operating frequency should be selected to ensure that the valve can respond quickly and meet system requirements. At the same time, in order to improve the reliability of valve operation, a driving method with anti-misoperation functions and safety protection measures should be selected.

4. Environmental conditions and installation space: Environmental conditions and installation space are also one of the factors in selecting the driving method of the micro air valve. In an environment with limited space, a compact driving method should be selected, such as electric drive or pneumatic drive, etc.; in harsh environments You should choose a drive mode with waterproof, dustproof and other functions.

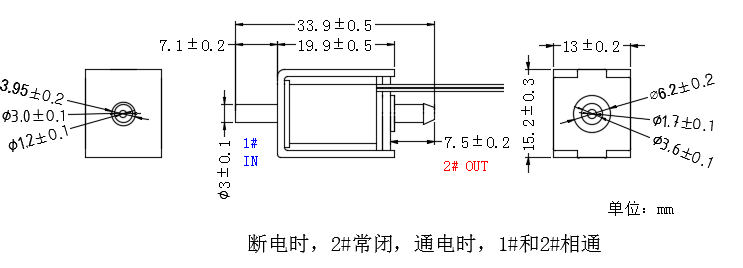

Dimension Structure

Valve reliability and lifespan

Valve reliability and service life are one of the important technical indicators of miniature normally closed valves, and are also one of the key issues that customers pay attention to. In order to improve the reliability and life of the mini air control valve, the following aspects need to be paid attention to:

1. Material selection and quality control: Selecting materials with excellent performance is the basis for improving the reliability and life of the Micro Solenoid Air Valve. At the same time, strengthening the quality control of the production process can reduce the rate of defective products and failure rates, thereby improving the quality stability of the valve.

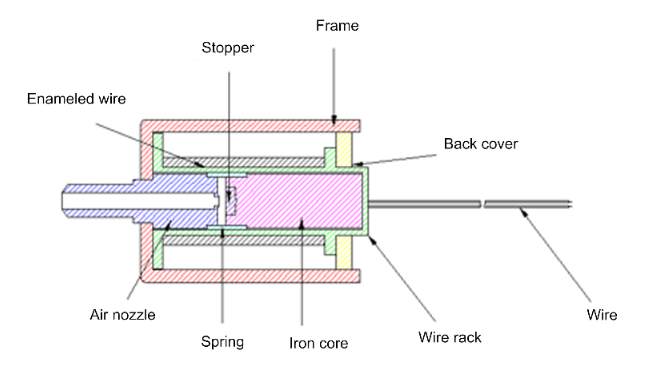

2. Structural design: Reasonable structural design can effectively reduce stress concentration and fatigue damage caused by the valve during operation, thereby improving its reliability. The following is a detailed analysis of the reliability and life of the miniature normally closed valve:

3. Lubrication and maintenance: Good lubrication can reduce friction and wear and extend the service life of th dc micro air valve. According to the working conditions and requirements of the valve, select the appropriate lubricant and lubrication method, and perform regular lubrication and maintenance. At the same time, it should be noted that the selection and use of lubricants should comply with relevant standards and specifications to prevent any impact on valve performance and fluid.

4. Environmental adaptability: The environmental conditions in which the valve is located also have a great impact on its reliability and life. For example, environmental conditions such as high temperature, low temperature, corrosive media, and vacuum will affect the valve material and structure, reducing its reliability and life. Therefore, it is necessary to select appropriate materials and structures according to the actual working environment, and take corresponding protective measures to improve the adaptability and durability of the valve.

5. Installation and use: Correct installation and use are also important factors affecting the reliability and life of the valve. During the installation process, the installation must be carried out in accordance with the specified requirements to ensure that the position, direction and connection method of the valve are correct. During use, it is necessary to operate in accordance with the prescribed operating procedures to avoid adverse operating conditions such as overloading, overpressure, and overheating, thereby extending the service life of the valve.