What are the driving mechanisms of micro piston pumps?

The driving mechanism of the Mini piston pump is a mechanism that realizes the reciprocating motion of the piston, and is mainly composed of a power source, a transmission mechanism, a guide mechanism, a sealing mechanism and a control mechanism.

1. Power source

The power source is a component that provides driving force. Commonly used power sources include motors, pneumatic motors, etc. The motor generally uses a DC motor or a stepper motor, which has a smaller volume and higher speed, and is suitable for occasions that require larger flow rates. Pneumatic motors are suitable for occasions that require larger pressure and flow. Their advantages are that they can adjust flow within a larger pressure range and have lower requirements on the working environment.

2. Transmission mechanism

The transmission mechanism is a component that transmits the power of the power source to the piston. Commonly used transmission mechanisms include crankshaft eccentrics, chains, etc. The crankshaft eccentric is a mechanism that converts the rotational motion of the motor into reciprocating motion. It has the advantages of simple structure and convenient processing. Chains are suitable for longer distance transmission and can transmit larger forces and torques.

3. Guidance mechanism

The guide mechanism is a guide and support component that controls the reciprocating motion of the piston. Commonly used guide mechanisms include guide rails, bearings, etc. Guide rails are usually made of metal or plastic and have good wear resistance and corrosion resistance. Bearings are suitable for high-speed operation and can reduce friction and wear.

4. Sealing mechanism

The sealing mechanism is a component that prevents leakage of fluid media. Commonly used sealing mechanisms include O-rings, lip seals, etc. O-rings have good elasticity and sealing performance, while lip seals are suitable for high-pressure situations and can withstand greater pressure without leaking.

Technical Specification

| Product model | DHBZK68

| Voltage | DC12V |

| Pressure | 12bar | Noise | 58db |

| Vacuum | -0.3bar | Lifespan | 20000 times |

| Working temperature | 5-55℃ | Application | Coffee machine |

How to realize the driving mechanism of micro Piston Pump ?

The implementation process of the driving mechanism of the DC Piston pump is usually as follows:

1. The power source provides driving force: The power source (such as motor, pneumatic motor, etc.) generates driving force and transmits it to the transmission mechanism.

2. The transmission mechanism converts the form of motion: The transmission mechanism (such as crankshaft eccentric, chain, etc.) converts the rotational motion of the power source into the reciprocating motion of the piston.

3. The guide mechanism controls the movement trajectory of the piston: The guide mechanism (such as guide rails, bearings, etc.) controls the movement trajectory of the piston to ensure that the piston can perform accurate reciprocating motion.

4. The sealing mechanism prevents medium leakage: The sealing mechanism (such as O-ring, lip seal, etc.) prevents fluid medium from leaking and ensures the normal operation of the piston pump.

5. The control mechanism adjusts the flow and pressure: The control mechanism (such as speed regulator, pressure regulator, etc.) adjusts the reciprocating speed and flow of the piston according to actual needs to realize the flow and pressure regulation of the micro piston pump.

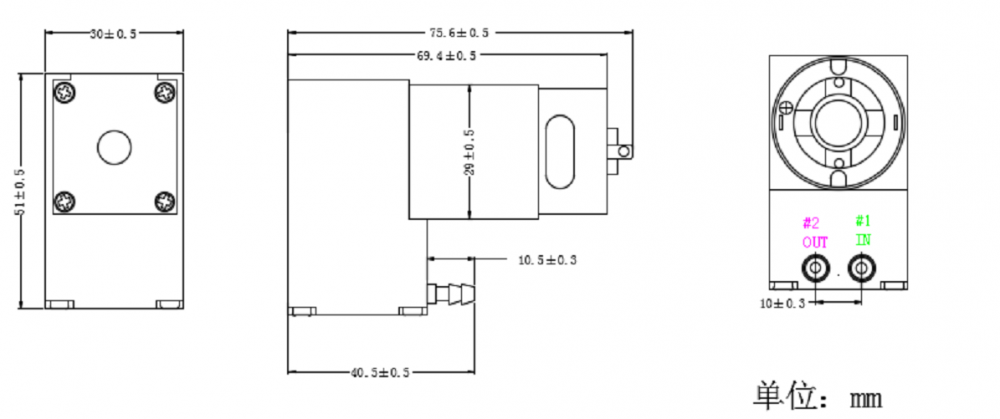

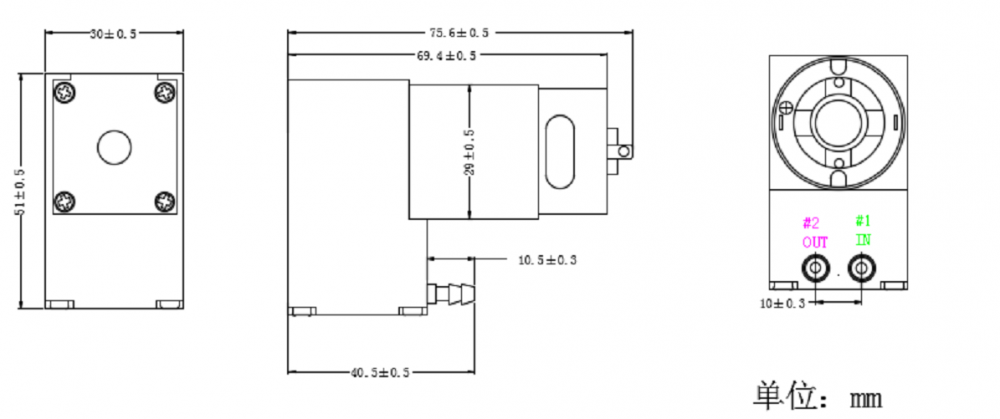

Dimension

How does the driving mechanism of the micro piston pump realize the suction and discharge of fluid media?

The driving mechanism of the Diaphragm Piston Pump achieves the suction and discharge of fluid media through the following steps:

1. When the piston moves upward, the volume in the cylinder increases, forming a low-pressure area. At the same time, the suction valve opens, allowing liquid from the reservoir or other container to enter the cylinder.

2. When the piston moves downward, the volume in the cylinder decreases, forming a high-pressure area. At the same time, the suction valve closes, preventing the liquid from flowing back. Under the action of high pressure, the discharge valve opens, and the liquid is forced out of the pump body and sent to the required system or equipment.

3. When the piston moves upward again, the suction valve reopens, allowing the liquid to enter the cylinder again. Through this reciprocating motion, the micro piston pump can continuously suck in and discharge the liquid, completing the transportation and compression of the liquid.

DYX Mini Pumps And Solenoid Valves Application

What are the main components of a micro piston pump?

The main components of the piston Mini Water Pump include the pump body, piston, suction valve, discharge valve and driving mechanism. The functions of these parts are as follows:

1. Pump body: The pump body is the basic component of the micro piston pump and is usually made of aluminum alloy or engineering plastics. It has good mechanical properties and corrosion resistance, which can ensure the normal operation and long service life of the pump.

2. Piston: The piston is the core component of the piston Micro Water Pump, usually made of stainless steel or copper alloy. The function of the piston is to realize the suction and discharge of fluid, and its movement speed and number of reciprocations can be adjusted through the driving mechanism.

3. Suction valve: The suction valve is a component that controls fluid suction, usually made of stainless steel or copper alloy. A suction valve is installed at the suction inlet of the pump. When the piston moves backward, the suction valve opens and the fluid is sucked into the pump.

4. Discharge valve: The discharge valve is a component that controls the discharge of fluid, usually made of stainless steel or copper alloy. When the piston moves forward, the discharge valve opens and fluid is discharged from the pump.

5. Driving mechanism: The driving mechanism is an important component of the micro piston pump and is used to drive the piston for reciprocating motion. According to actual needs, different driving mechanisms can be selected, such as motors, pneumatic motors, etc.

In addition, the micro piston pump also has other auxiliary parts, such as bearings, oil seals, gaskets, etc. The function of these parts is to ensure the normal operation and sealing performance of the pump.

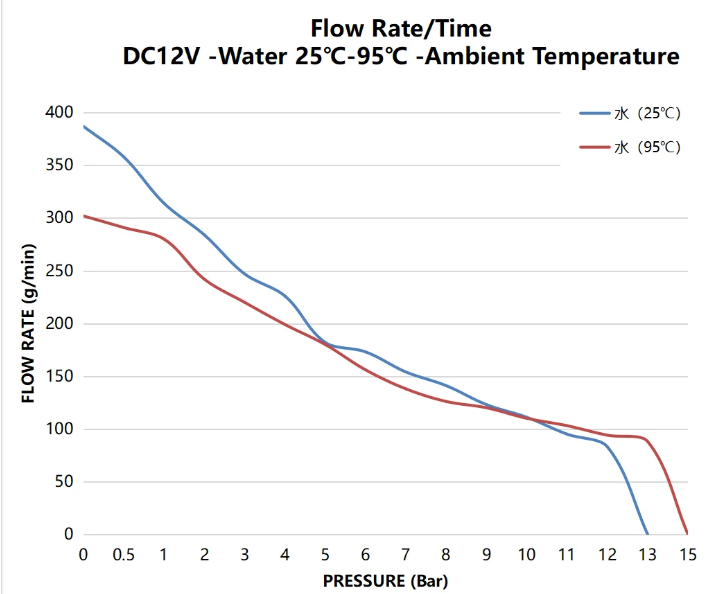

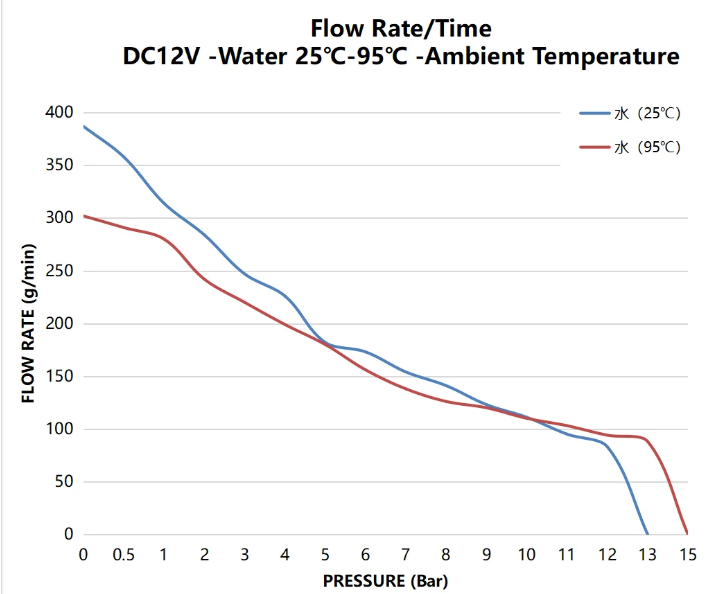

Mini Piston Pump Flow Test Curve

How to calculate the flow rate of a micro piston pump?

The flow rate of a micro piston Self Priming Micro Water Pump can be calculated in a variety of ways, depending on the pump design and usage conditions. Here are some common calculation methods:

1. Volume flow method: The volume flow method is the most direct calculation method. It determines the flow rate by measuring the volume of liquid delivered by the micro piston Mini DC Liquid Pump per unit time. Volumetric flow is typically measured using a flow meter that accurately measures the volume of liquid passing through the pump.

2. Rotational speed flow method: The rotational speed flow method is a method of determining the flow rate by measuring the rotation speed of a micro piston pump. Assuming that the efficiency of the pump remains constant, the volumetric flow rate of the fluid is proportional to the rotational speed. Therefore, by measuring the rotational speed, the flow rate can be calculated.

3. Pressure flow method: The pressure flow method is a method of determining the flow rate by measuring the outlet pressure of the micro piston pump. Under certain conditions, the outlet pressure is proportional to the density and volume flow of the fluid. By measuring the outlet pressure, combined with the density data of the fluid, the flow rate can be calculated.

4. Current method: For some micro piston pumps, the current of the motor is related to the pump speed and load. By measuring the current of the motor, combined with the design parameters of the pump and the speed-current relationship curve, the flow rate can be calculated indirectly.

5. Weighing method: The weighing method is a method of determining the flow rate by measuring the mass of liquid delivered by the piston Mini DC Hydraulic Pump per unit time. The mass flow rate of a fluid can be determined by collecting the transported fluid in a container and weighing it. Combining the pump design parameters and fluid density data, the volumetric flow rate can be calculated.