What are the two types of piston pumps?

Piston pumps are mainly divided into two types: simple piston pumps and compound piston pumps.

Simple piston pumps have only a one-way valve that moves fluid in one direction. This type of pump usually has a compact structure, large flow rate, and high delivery pressure, and is suitable for many industrial fields.

Such as petroleum, chemical industry, paper making, etc.

A compound Piston Pump consists of two or more pistons and valves, which can realize forward and reverse fluid transportation. Compared with conventional piston pumps, compound piston pumps have the advantages of easy steering, adjustable flow, and energy saving.

It has unique features such as energy and environmental protection and has broad application prospects.

In addition, according to their working principles, piston pumps can also be divided into single-acting pumps and double-acting pumps. Double-acting pumps are suitable for situations where there is suction and pressure. Because they run in two directions and have back-and-forth motion, they are called double-acting pumps. Single-acting pumps are only suitable for one-way movement of pressure or suction. When pressing in one direction, the valve plate in the other direction is closed and cannot move back and forth.

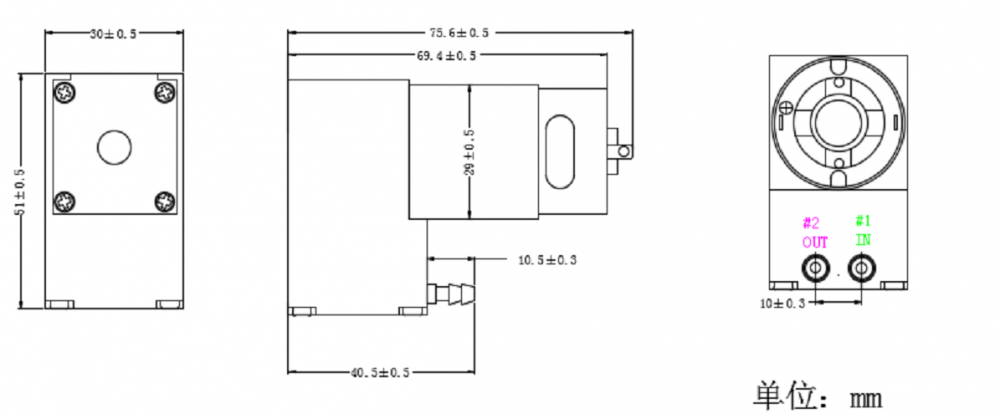

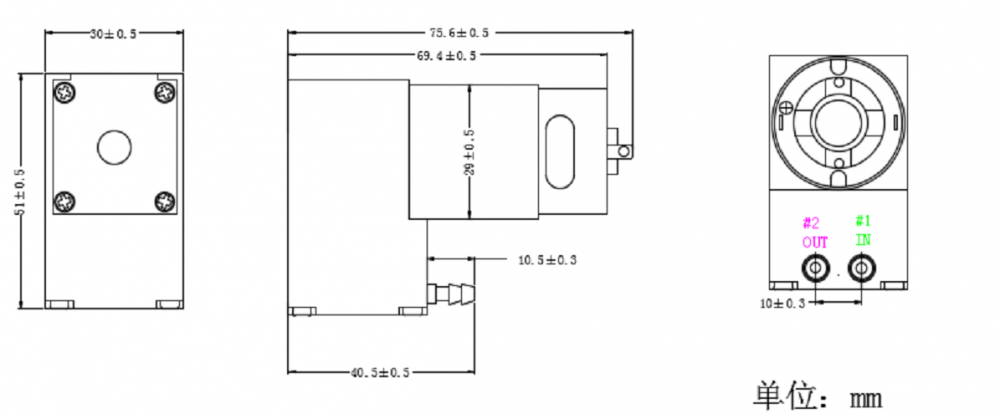

Technical Specification

| Product model | DHBZK68

| Voltage | DC12V |

| Pressure | 12bar | Noise | 58db |

| Vacuum | -0.3bar | Lifespan | 20000 times |

| Working temperature | 5-55℃ | Application | Coffee machine |

What are the advantages and limitations of piston pumps in industrial applications?

The advantages of Piston Spring in industrial applications mainly include: 1. High pressure range: Piston pumps usually have a high working pressure range and can meet various pressure needs in industrial production.

2. Transport a variety of media: The DC Piston pump can transport a variety of media, including liquids, gases, etc., and has wide applicability.

3. Adjustable flow: By changing the stroke or rotation speed of the piston, the flow of the piston pump can be adjusted to meet the needs of different process flows.

4. High reliability: The piston pump has a relatively simple structure and few wearing parts, so it has high reliability and long service life.

5. Low maintenance cost: The maintenance cost of the piston pump is relatively low because it has fewer parts and the maintenance work is relatively simple.

However, piston pumps also have some limitations in industrial applications:

1. Not suitable for large flow occasions: The flow rate of the Diaphragm Piston Pump is relatively small, so it is not suitable for occasions that require large flow transportation.

2. Relatively low efficiency: Compared with some other types of pumps, piston pumps may be less efficient because of their greater mechanical friction losses.

3. High requirements on the medium: Piston pumps have certain requirements for the cleanliness and viscosity of the conveyed medium. It is necessary to pay attention to the quality of the medium during the application process.

4. Louder noise: The piston pump will produce loud noise during operation, and corresponding noise reduction measures need to be taken.

5. Consumable parts need to be replaced regularly: Some consumable parts in the piston pump, such as pistons, sealing rings, etc., need to be replaced regularly, which increases the cost of use.

How does the piston of a Mini piston pump achieve reciprocating motion?

The reciprocating motion of the piston of the piston Micro Water Pump mainly relies on the crankshaft and connecting rod mechanism. A crankshaft is a mechanical device that converts rotational motion into reciprocating motion, usually driven by an electric motor or other power source. There are one or more cranks on the crankshaft. The cranks are connected to one end of the connecting rod, and the other end of the connecting rod is connected to the piston. When the crankshaft rotates, the crank and connecting rod move with it, causing the connecting rod to drive the piston to reciprocate in the cylinder. Specifically, when the crankshaft rotates clockwise, the connecting rod is pushed to move to the right, causing the piston to move to the right, realizing the suction and discharge of liquid; when the crankshaft rotates counterclockwise, the connecting rod is pushed to move to the left, causing the piston to move to the right. Left movement. By continuously repeating this process, the piston achieves reciprocating motion and completes the suction, compression and discharge of liquid.

In addition, in micro piston pumps, the cylinder is usually designed to be circular with a track for piston movement inside. The piston moves along a track within the cylinder, generating pumping pressure through friction with the cylinder wall. In order to reduce friction and wear, the inner wall of the cylinder is usually hardened, while the surface of the piston is coated with lubricating oil or made of materials with good lubrication properties.

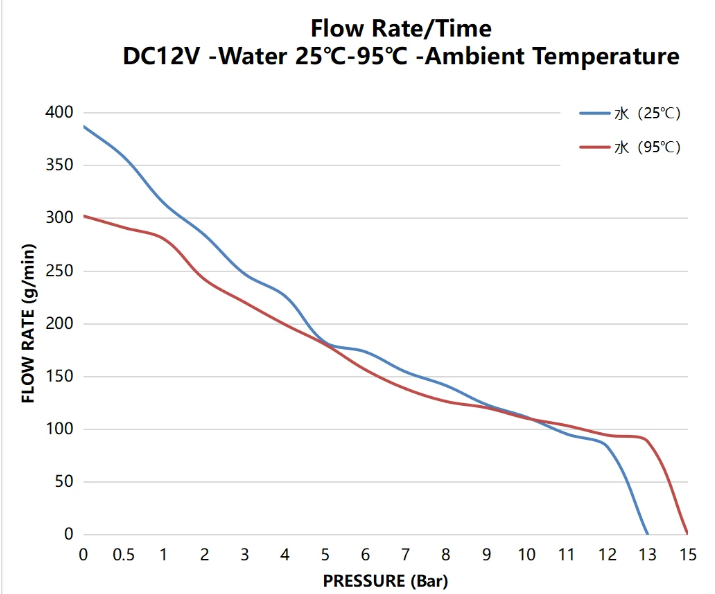

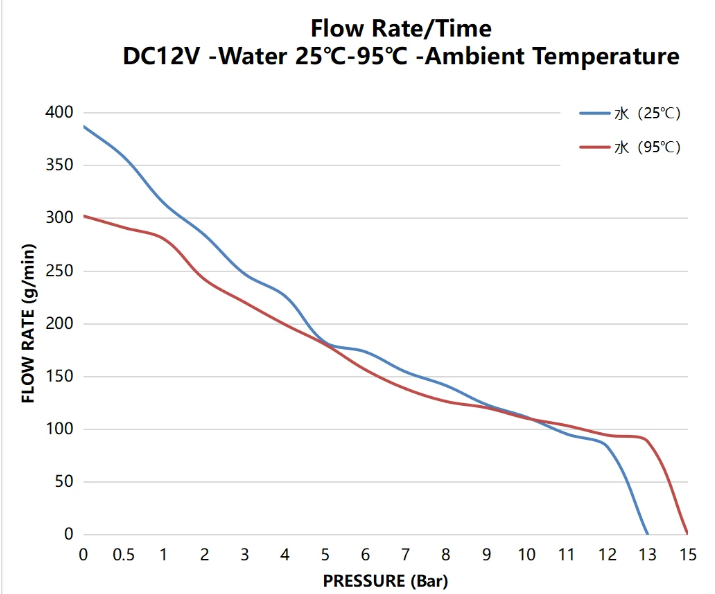

Piston pump flow test curve

How to generate pumping pressure during the piston movement of a micro piston pump?

In a piston Mini Water Pump, the generation of pumping pressure during piston movement is mainly achieved through the following steps:

1. Suction stage: When the piston moves toward the inlet end of the pump, the volume in the pump chamber gradually increases, forming a certain degree of vacuum. When the inlet valve is open, external liquid is sucked into the pump chamber. As the piston continues to move toward the inlet end, the liquid in the pump chamber gradually increases, and at the same time, the inlet

The valve is closed to prevent liquid from flowing back.

2. Compression stage: When the piston starts to move toward the outlet end, the volume in the pump chamber gradually decreases and the liquid is compressed. At this time, the outlet valve is closed and the liquid in the pump chamber is under pressure. As the piston continues to move toward the outlet end, the liquid pressure in the pump chamber gradually increases.

3. Discharge stage: When the piston reaches its maximum stroke, the liquid pressure in the pump chamber reaches its highest point. Subsequently, the piston begins to move toward the inlet end, the outlet valve opens, and the high-pressure liquid is discharged out of the pump. As the piston continues to move toward the inlet end, the volume in the pump chamber gradually increases.

Prepare for the inhalation and compression process.

By continuously repeating the above process, the piston Mini DC Liquid Pump can deliver liquid in continuous operation and generate stable pumping pressure. It should be noted that the movement speed of the piston, the crankshaft

Factors such as rotation speed and cylinder volume will affect the pumping pressure and flow rate of the micro piston pump. In practical applications, the micro piston pump needs to be reasonably designed and adjusted according to specific needs to obtain the best performance.

DYX Mini Pumps And Solenoid Valves Application

What are the specific aspects of piston Mini Diaphragm Pump efficiency problems?

The efficiency problems of piston pumps are mainly reflected in the following aspects: 1. Mechanical friction loss: Mechanical friction loss in piston pumps is mainly caused by friction between moving parts. For example, the friction between the piston and the cylinder, the friction of the bearing, etc. will cause certain mechanical losses, thus affecting the efficiency of the piston Membrane Water Pump. 2. Fluid friction loss: When the piston DC Pump transports fluid, the friction between the fluid and the flow channel wall and the friction between the fluid interior will also cause certain losses. The size of fluid friction loss depends on the properties of the fluid, flow rate, flow channel structure and other factors. 3. Volumetric efficiency of the pump: Volumetric efficiency refers to the ratio of the volume flow rate delivered by the pump per unit time to the theoretical volume flow rate. If the volumetric efficiency of the piston pump is low, it means that the actual flow rate of the pump is less than the theoretical flow rate, which may be due to factors such as leakage and friction. 4. Hydraulic efficiency of the pump: Hydraulic efficiency refers to the ability of the pump to do work on the fluid. The lower hydraulic efficiency indicates that the pump does less work on the fluid when transporting the fluid, which may be caused by the frictional resistance, leakage and other factors of the fluid. 5. Total efficiency of the pump: Total efficiency refers to the product of the mechanical efficiency and volumetric efficiency of the pump. The overall efficiency is an important indicator that comprehensively reflects the performance of the piston pump. Low overall efficiency indicates that the piston pump suffers large losses in both mechanical and volumetric aspects.