What is the difference between double acting piston pumps and single acting piston pumps used in food packaging machines?

The main difference between the double acting Piston Pump and the single acting piston pump used in food packaging machines lies in their working principle and performance characteristics.

A double acting piston pump is a DC Pump that can generate thrust in both directions. In each working cycle, both pistons will work simultaneously work, one piston is sucking in liquid, and the other piston is discharging liquid. This design enables the pump to provide continuous and stable flow quantity, suitable for food packaging machines that require precise control and uniform filling. In addition, double acting piston pumps typically have higher efficiency and longer service life, as they can share workload in two directions and reduce wear on individual pistons.

A single acting piston pump has only one piston in operation, and it can only generate thrust in one direction when suction and discharge liquids. such pumps are usually simpler and cheaper, but the flow rate may not be as stable as double acting piston pumps. Single acting piston pumps may be more suitable for some simple applications that do not require precise flow control.

In food packaging machines, double acting piston pumps are usually more suitable due to the need for precise liquid measurement and consistent filling speed.

Technical Specificaiton

| Model | DHB-ZK65

| Voltage

| DC12.0V

|

Current

| <900mA

| Pressure

| <-75Kpa

|

Air flow rate

| 7L/Min

| Media

| Air

|

Life cycle

| 800 hours

| Product use

| massage equipments, vacuum package machine, vacuum fresh keeping box and vacuum blender.

|

Is a Piston Type Vacuum Pump a reciprocating pump?

Yes, piston pump is a type of reciprocating pump. A reciprocating pump refers to a pump that uses pneumatic or mechanical means to make a certain working fluid move back and forth within a certain volume range, thereby achieving transportation or pressurization. A piston pump changes the volume of the cylinder by reciprocating the piston within a certain volume range, allowing the liquid to be sucked in and compacted from the inlet, and then discharged through the outlet, thereby achieving the function of conveying or pressurizing. Therefore, piston pumps fully comply with the definition and working principle of reciprocating pumps

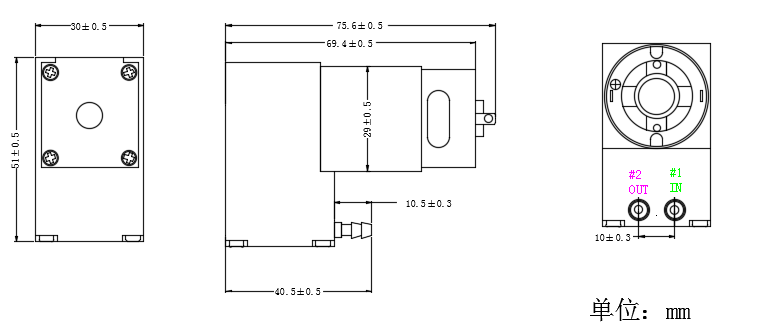

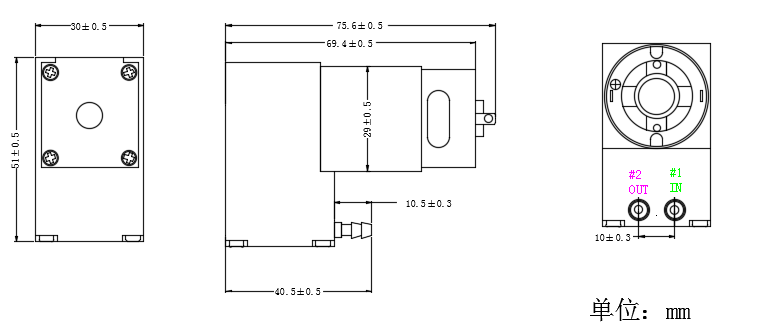

Dimension Drawing

Can the Mini Piston Vacuum Pump be reversed?

It is usually not recommended to use piston pumps upside down for the following reasons:

Valve design: The valve in a piston pump is designed to guide the fluid in a specific direction. Using it upside down may cause the valve to malfunction, making it difficult for the pump to effectively suction or discharge fluid.

Fluid path: The fluid path of a piston pump is unidirectional during design and manufacturing. Using it upside down may alter the path of the fluid, preventing it from entering or leaving the pump body correctly.

Mechanical structure: The mechanical structure of a piston pump, such as the piston, connecting rod, and driving mechanism, is usually designed for one-way operation. Reverse use may cause unnecessary stress and friction on these components, leading to damage or performance degradation.

Safety hazard: If the piston pump is used upside down incorrectly, it may cause damage, leakage, or other safety issues to the pump.

DYX Mini Pumps And Solenoid Valves Application

Will micro diaphragm piston pumps suffer from cavitation?

Cavitation, also known as cavitation, refers to the phenomenon of pitting corrosion and damage on the metal surface in contact with a fluid under high-speed flow and pressure changes. This phenomenon often occurs in the high-speed pressure reduction zone at the blade end of centrifugal pumps, where the cavity is crushed in the high-pressure zone and generates impact pressure, damaging the protective film on the metal surface and leading to an accelerated corrosion rate. The characteristic of cavitation is the formation of many small pits on the metal surface, which gradually expand into caves.

For micro diaphragm piston pumps, although their working principle is different from some types of Diaphragm Pumps, under certain conditions, especially when the water temperature is high and the vacuum degree of the pump is low, the pressure in the suction stroke pump chamber may be lower than the saturated vapor pressure of water at that temperature, causing water to vaporize and produce a large number of bubbles. During the compression stroke, these bubbles quickly burst under the action of high pressure, generating high-frequency and high impact water hammer, continuously striking the internal components of the pump. This phenomenon can cause pump vibration, generate noise, and may damage components, reduce efficiency, resulting in cavitation.

Therefore, micro diaphragm piston pumps may experience cavitation under specific conditions. To avoid or reduce the impact of cavitation, it is possible to consider improving the design of the pump body, optimizing its working principle, and paying attention to the working conditions of the pump, such as water temperature, vacuum degree, and other factors. At the same time, regular maintenance and inspection of the pump's condition are also very important to ensure its normal operation and extend its service life.