Swimming Pool Ceaning Robot DC Pump And Valve

$91000-9999 Piece/Pieces

$7.8≥10000Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,EXW,FCA,DDU,DDP,Express Delivery,CIF |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

$91000-9999 Piece/Pieces

$7.8≥10000Piece/Pieces

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,EXW,FCA,DDU,DDP,Express Delivery,CIF |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

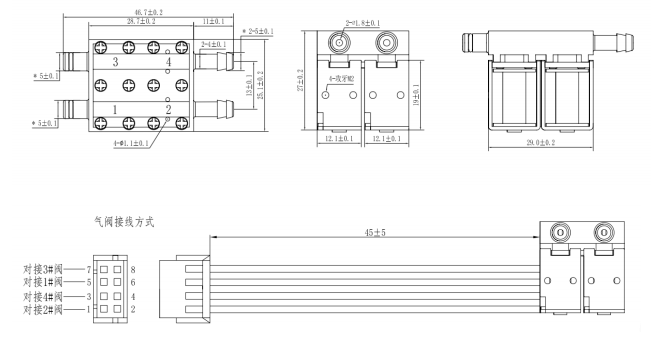

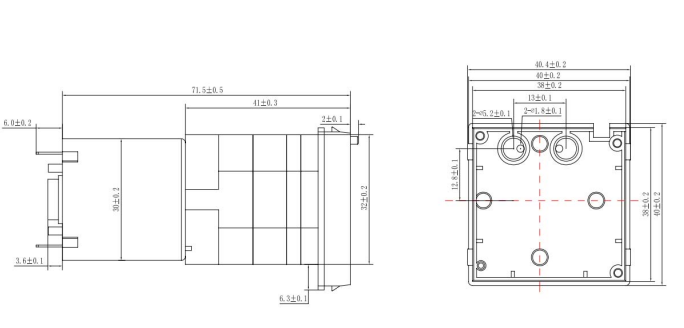

Model No.: DQB421-D

Brand: DYX

Environment: 5℃ ~55℃

Current: <350mA

Life Test: >30,000cycles

Rated Voltage: DC3.0V

Product Model: DQB030-A

Media: Air

Noise Level: <60db@30cm

Flow Rate: 0.4L/MIN

NW: 52

Mico DC Pump valve integration is a structure that integrates Mini Pumps and valves and is often used in swimming pool cleaning robots.

For swimming pool cleaning robots, the Mini DC Pump and valve integration has the following common sense:

1. Working principle: The micro pump and valve body contains a micro pump and a valve. The valve is responsible for controlling the direction and flow of water flow. The function of the micropump is to generate water flow and realize different cleaning modes of the swimming pool cleaning robot through the control of valves.

2. Advantages: The advantages of the integrated micro pump and valve are compact structure, small size, light weight, and easy to install on the swimming pool cleaning robot. At the same time, because the micro pump and valve are integrated, the water flow can be better controlled and cleaning efficiency improved.

3. Classification: The integrated Micro DC Pump and valve can be divided into different types according to the use requirements, such as ordinary type, anti-clogging type, high temperature type, etc. Different types of micro pump valves are suitable for different use environments and needs.

4. Maintenance: The maintenance of the micro pump and valve mainly includes regular cleaning and replacement of filters. During maintenance, it is necessary to turn off the water source first, and then disassemble the micro pump valve for cleaning. It should be noted that when installing the integrated micro pump and valve, you need to ensure that the installation is correct to avoid affecting the use effect.

5. Application scope: The integrated micro pump and valve is often used in swimming pool cleaning robots, aquarium cleaning, industrial water treatment and other fields. In these areas, the integrated micro pump and valve can help achieve efficient, fast, and convenient cleaning and filtration.

The integrated Small DC Pump and valve has the following functions in improving the cleaning efficiency of swimming pool cleaning robots:

1. Generate strong water flow: The micro-pump inside the micro-pump valve can generate strong water flow, thereby washing away dirt and impurities on the surface of the swimming pool. This powerful water flow can effectively remove dirt and impurities from the pool surface and improve cleaning efficiency.

2. Control the direction and flow of water flow: The valve inside the micro-pump valve can control the direction and flow of water flow, allowing the swimming pool cleaning robot to clean different parts of the swimming pool more flexibly. For example, by controlling the opening and closing of the valve, the size and direction of the water flow can be controlled, thereby achieving efficient cleaning of the edges, bottom and walls of the pool.

3. Achieve multiple cleaning modes: Multiple types of micro pump and valve integration can be selected according to different use needs, thereby achieving different cleaning modes. For example, the anti-clogging micro pump-valve integrated can effectively prevent clogging when the water quality is poor, and the high-temperature micro pump-valve integrated can work normally in high temperature environments. These different cleaning modes can be selected according to the actual conditions and needs of the pool, thereby improving cleaning efficiency.

4. Improve cleaning coverage: The integrated micro pump and valve can be installed in different parts of the swimming pool cleaning robot to increase cleaning coverage. For example, a micro-pump valve can be integrally installed on the bottom or side of a swimming pool cleaning robot, allowing it to clean different parts of the pool more comprehensively.

Quick Detail:

| Voltage | DC12V | Power | 1.8W |

| Pressure | 0-60Kpa | Used fluid | Air |

| Resistence | Resistance:80±5%Ω | Frustrated speed | ≤4S |

Does the integrated micro pump and valve have resistance?

The micro pump valve has a certain resistance capability, but the specific resistance performance will vary depending on the product type and usage requirements. Generally speaking, the impact of fluid resistance on its performance will be considered when designing the integrated micro pump and valve, and corresponding measures will be taken to improve the resistance performance.

In the integrated design of micro pump and valve, some materials and structures with better resistance properties can be used, such as high-strength, wear-resistant materials, and optimized flow channel structures. In addition, the resistance performance can be improved by adding resistance components (such as filters, silencers, etc.).

It should be noted that the resistance performance of the integrated micro pump valve is not a fixed value, but will be affected by a variety of factors, such as fluid properties (viscosity, density, etc.), pipeline resistance, etc. Therefore, in actual use, it is necessary to select a suitable micro-pump-valve integration according to specific application scenarios and requirements, and consider the impact of fluid resistance on its performance.

If you need to know the impedance performance of a specific micropump-valve unit, it is recommended to refer to the relevant product manual or consult the manufacturer's technical support personnel.

The micro pump-valve combination is an efficient, compact pump and valve combination that is widely used in various fluid systems. In order to ensure the performance and quality of the integrated micro pump valve, a series of rigorous tests are required. The following is a general micro pump valve integrated testing process:

1. Appearance inspection

First, check the appearance of the integrated micro pump and valve, including checking whether there are scratches, deformations, cracks and other defects on the appearance, as well as whether there is coating peeling off, etc. At the same time, it is also necessary to check whether the installation dimensions and interface dimensions of the micro pump and valve body meet the design requirements.

2.Performance test

Performance testing mainly includes tests on flow, head, power, efficiency, etc. Before testing, the micropump valve needs to be installed integrally on the test device and the connecting pipes and seals must be intact. Then, perform performance testing according to the specified test conditions, record flow, head, power and other parameters, and calculate efficiency.

3.Tightness test

The sealing test is one of the important steps in testing the integration of micro pump and valve. It is necessary to check whether the individual seals of the micro pump valve are intact and have sufficient sealing performance. Generally, the test is carried out by pressurizing a certain pressure of water or gas into the micro pump and valve body to observe whether there is leakage.

4. Withstand voltage test

The pressure test is to test the maximum pressure that the micro pump and valve can withstand. During the test, the micro-pump and valve need to be installed integrally on the test device, and the pressure is gradually increased until the micro-pump and valve integrally breaks or leaks. Record the maximum pressure value to ensure that the micro pump and valve can withstand the design pressure during actual use.

5. Action test

The action test is to test whether the opening and closing of the micro pump valve is flexible and reliable. It is necessary to manually or automatically control the opening and closing of the micro pump valve, observe whether its movement is smooth and sensitive, and check whether there is any sticking phenomenon.

6.Noise test

The noise test is to test the noise generated by the micro-pump and valve body during its working process. The micro pump valve needs to be installed integrally on the test device, and the noise test must be performed according to the prescribed test method to record the noise value.

7. Electrical testing

For electric micropump-valve integration, electrical testing is required to verify its electrical performance. Generally include motor operation test, overload test, insulation resistance measurement, etc. Appropriate electrical test equipment needs to be used to make measurements and record relevant data.

8.Reliability test

The reliability test is to evaluate the stability and reliability of the micro pump and valve integration in actual use. Generally, long-term running tests, low-temperature tests, high-temperature tests, humidity tests, etc. are required to test the performance and reliability of the micro-pump and valve integrated under different environmental conditions.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.