Portable 12v DC Pump For Medical Nebulizer

$4.051000-9999 Piece/Pieces

$3≥10000Piece/Pieces

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shekou,Yantian |

$4.051000-9999 Piece/Pieces

$3≥10000Piece/Pieces

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shekou,Yantian |

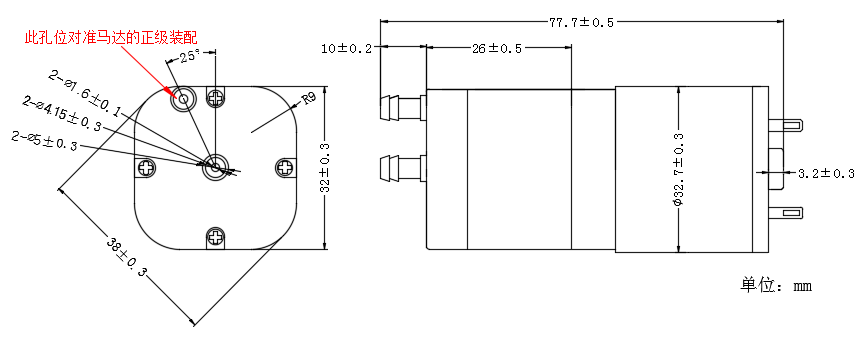

Model No.: DQB421-A

Working Temperature: 5℃ ~55℃

Service: Customized OEM

Media: Air

Noise Level: <55db

Rated Voltage: DC6.0V 12.0V 24.0V

Life Test: >400 hours

Air Flow Rate: 5.0-6.0LPM

Pressure: 600-850mmHg

N.W.: 110g

Model No.: DQB421-A

| Selling Units | : | Piece/Pieces |

How does a Mini Air Pump achieve spraying such small mist in an atomizer?

The micro air pump can spray small mist in the atomizer, mainly relying on its working characteristics and combined with the structural design of the atomizer.The basic working principle of a micro diaphragm air pump is to drive the reciprocating motion of the diaphragm through the rotation of the motor. During each reciprocating process of the diaphragm, it creates an alternating environment of positive and negative pressure. When the diaphragm moves forward, it compresses the space inside the pump body, generating positive pressure and pushing the liquid into the pump body from the inlet; When the diaphragm moves backwards

When moving, the internal space of the pump body expands, forming a negative pressure that sucks out the liquid from the outlet. This alternating change of positive and negative pressure causes the liquid to be continuously sucked in and pushed out of the pump body, thereby achieving liquid circulation.

In atomizers, the main function of a Dc Air Pump is to generate sufficient pressure to decompose the liquid into small mist droplets. The structure of an atomizer typically includes a liquid storage tank, a miniature diaphragm air pump, and a nozzle. When the micro diaphragm air pump is working, it extracts the liquid from the storage tank and sprays it out at high pressure through a nozzle.

The design of the nozzle is crucial, as it typically has a very small aperture, so when liquid passes through, it is subjected to great pressure and dispersed into tiny droplets.

In addition, atomizers may also utilize the effect of air flow to further refine droplets. By introducing additional air flow, the surface area of the liquid can be increased, making it easier to disperse into small droplets.

What is the air flow of a micro diaphragm air pump?

In a micro diaphragm air pump, the air flow mentioned does not refer to the airflow generated by the air pump itself, but rather to the airflow sprayed out from the outlet after the air or gas is sucked in and compressed through its internal mechanism during operation. This airflow can be air or other gases, depending on the application environment and purpose of the air pump.

In atomizers, the airflow generated by the portable electric air pump plays an important role. When the air pump is working, it will suck in the surrounding air (or other gases) and increase its pressure through an internal compression process. Subsequently, high-pressure gas passes through the nozzle of the atomizer and interacts with the liquid, helping to atomize the liquid into small droplets.

The main function of this airflow is to provide the energy and power required for atomization, as well as promote the uniform distribution and rapid evaporation of droplets.

Therefore, it can be said that the airflow generated by the Electric Air Pump in the atomizer is one of the key factors that help achieve the atomization effect. It interacts with liquids and disperses them into small droplets through the action of pressure and shear force, thereby meeting the needs of atomizers. At the same time, parameters such as airflow velocity, flow rate, and pressure

The number also needs to be adjusted and optimized according to specific atomization requirements to achieve the best atomization effect.

Technical Specification

| Model | DQB421-A | Voltage | dc6v 12v 24v |

| Current | 1000mA,550mA,300mA | Flow | 5-6LPM |

| Pressure | 600-850mmHg | Maxium vacuum pressure | -550mmHg |

| Leakage | smaller than 15mmHg | Life cycle | more than 400 hours |

How does a mini electric air pump achieve spraying such small mist in an atomizer?

Air flow plays an important role in atomizers, helping to achieve better atomization effects. The following are several key aspects of how air flow helps atomizers work:

1. Increase the surface area of fog droplets: When the liquid is sprayed out of the nozzle under high pressure, introducing appropriate air flow can cause the fog droplets to experience greater shear force during the spraying process. This leads to further refinement of the droplets, increasing their surface area and thus improving the efficiency of atomization.

2. Accelerate the evaporation of droplets: Air flow can increase the contact area between droplets and ambient air, accelerating the evaporation process of droplets. This is particularly important in certain application scenarios, such as in medical nebulizers, where rapid evaporation can help drugs enter the patient's respiratory tract more quickly.

3. Uniform distribution of fog droplets: By controlling the flow velocity and direction of the air flow, fog droplets can be distributed more evenly in space. This is particularly important for occasions requiring large coverage (such as agricultural spray, indoor humidification, etc.) to ensure that each area can obtain a uniform atomization effect.

4. Prevent droplet condensation: In some cases, if the ambient humidity is high, droplets may condense into larger water droplets. By introducing air flow, the humidity around the droplets can be reduced, the possibility of condensation can be reduced, and the droplets can be kept small and uniform.

5. Improve the transmission efficiency of droplets: Air flow can serve as a transport mechanism to help droplets diffuse from the atomizer to the desired environment. Appropriate air flow rate and direction can make it easier for droplets to reach the target area and reduce diffusion losses in the air.

What effect does the flow rate in a Micro diaphragm pump have on the atomizer?

The flow rate in a Small DC Air Pump refers to the amount of liquid conveyed by the pump per unit time, usually expressed in liters per minute (L/min) or cubic meters per hour (m3/h). In a dewater, flow rate is a key parameter that has a significant impact on the atomization effect.

The flow rate determines the amount of liquid passing through the atomizer per unit time, which in turn affects the size and quantity of droplets. A larger flow rate means more liquid is atomized, producing more droplets, which helps improve the coverage and effectiveness of atomization. However, excessive flow rate may also lead to excessive droplet size, resulting in poor atomization effect

Uneven or excessive foam.

In addition, the flow rate is also related to the operating pressure of the atomizer and the physical properties of the liquid. Generally speaking, higher operating pressure can produce smaller droplets, but this also requires corresponding flow to support. Meanwhile, physical properties such as viscosity, density, and surface tension of liquids can also affect the selection of flow rate and the effectiveness of atomization.

Performance test

The ability of atomizers to spray fine mist is mainly influenced by which components inside the micro diaphragm pump?

2. Pump body: The design and material of the pump body can also affect the atomization effect. The internal structure and volume of the pump body determine the working capacity and efficiency of the pump, while the material determines the durability and adaptability of the pump to liquids. Appropriate pump body design and high-quality materials can ensure the stability of the pump during operation, avoid leakage or blockage, and thus ensure the continuity and uniformity of atomization.

3. Driving mechanism: The driving mechanism of a electric air compressor pump, such as an electric motor or electromagnet, provides the power for the pump to work. The performance stability and efficiency of the driving mechanism will affect the speed and output of the pump, thereby affecting the atomization effect. A stable driving mechanism ensures that the pump operates at a constant speed, allowing the atomizer to continuously and stably spray fine mist

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.