Chocolate Dosing Peristaltic Pump DC12V

$3.231000-9999 Others

$2.35≥10000Others

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS,FCA,DDP,DDU,Express Delivery |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

$3.231000-9999 Others

$2.35≥10000Others

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS,FCA,DDP,DDU,Express Delivery |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Ningbo |

Model No.: DRB320A-01

Brand: DYX

MOQ: 1000pcs

OEM/ODM: Available

Voltage: DC12V

Power: 2.4W

Noise: <60db

Temperature: 5-90℃

Lifetime: >500H(1s on,1s off)

Net Weight: 20g

Flow: 32-48ML/MIN

Media: Water

| Selling Units | : | Others |

| Package Type | : | Standard carton |

Does a Micro Peristaltic Pump require back pressure?

Whether a Mini Peristaltic Pump requires backpressure depends on the specific application requirements and pump design. In some applications, back pressure may be necessary, such as in high viscosity fluid transfer or where precise control is required

traffic situation. Back pressure can provide better sealing performance and more stable fluid delivery, reducing leakage and air inhalation.

However, in the design of micro-peristaltic pumps, some pumps may not be designed with back-pressure interfaces or devices, so no back-pressure is required.

In addition, some micro-peristaltic pumps may adopt special designs, such as higher elasticity of the pump tube or self-priming capability, and these designs may not require back pressure.

How is the back pressure of the Micro DC Peristaltic Pump generated?

The way the back pressure is generated in the micro Peristaltic Pump is related to its working principle. In peristaltic pumps, back pressure is usually caused by the pressure on the fluid in the pipeline. When fluid passes through the tube of a peristaltic pump

When the fluid is in the pipeline, the fluid is squeezed, causing the pressure in the pipeline to increase, thus forming back pressure.

Specifically, when the roller of the Mini DC Peristaltic Pump rotates, it will squeeze the fluid in the pipeline, causing the fluid to move toward the outlet. Due to the incompressibility of the fluid, when the roller convection

When the body is squeezed, the pressure in the pipeline will increase accordingly, thus generating back pressure. In addition, if the pipeline is blocked or the fluid flow is not smooth, it will also cause the generation of back pressure.

Technical Specification

| Voltage | DC12V | Mode | DRB130A-01 |

| Power | 2.4W | Suction Value | -20Kpa |

| Flow | 32-48LPM | Noise | 60dB |

| Life test | 500 hours | Product use | Smart sweeper,hgih end water dispenser,handwash machine,cosmetics machine,fragrance machine |

What effect does the back pressure of a Small DC Peristaltic Pump have on its performance?

The back pressure of a DC Peristaltic Pump has a certain impact on its performance.

First, back pressure can affect the flow rate of a microperistaltic pump. When back pressure increases, the fluid in the pipeline is subject to greater pressure, making it more difficult for the fluid to pass through the pump tube, thus reducing the flow rate.

On the contrary, when the back pressure is reduced or there is no back pressure, the fluid passes through the pump tube more easily, and the flow rate increases accordingly.

Secondly, back pressure can affect the suction lift of a DC Electric Peristaltic Pump. Due to the existence of back pressure, the suction lift of the pump will be limited to a certain extent. If the back pressure is too large, it may affect the suction power of the pump, resulting in the suction stroke is reduced or the fluid cannot be sucked. Therefore, when selecting and using a micro peristaltic pump, the back pressure needs to be adjusted appropriately to ensure its normal performance.

In addition, back pressure may affect the life and stability of microperistaltic pumps. If the back pressure is too high or too low, it may cause problems such as premature wear of the pump tube or unstable flow, thus affecting the pump service life and stability.

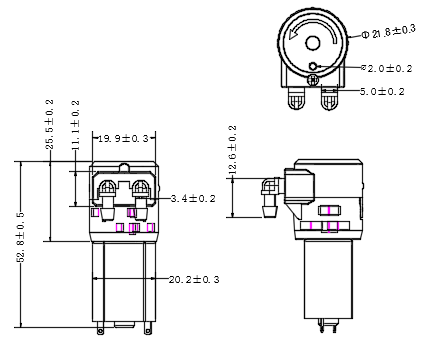

Dimension Drawing

Under what circumstances does a micro peristaltic pump need back pressure?

Micro peristaltic pumps may require back pressure under the following conditions:

1. High viscosity fluid: For high viscosity fluid, due to its poor fluidity, higher pressure is required to push the fluid through the pump tube. In this case, the back pressure can provide enough pressure to allow the fluid to pass through the pump tube smoothly and maintain a stable flow rate.

2. The flow rate needs to be precisely controlled: In some applications, the flow rate of fluid needs to be precisely controlled, such as in chemical reactions, biological experiments, or precision manufacturing. Back pressure can help stabilize fluid delivery and reduce flow fluctuations, thereby improving flow control accuracy.

3. Prevent gas mixing: In some applications, the DC Circulating Peristaltic Pump may inhale air or generate bubbles. The back pressure can effectively remove the gas in the pump tube and reduce the mixing of gas into the fluid, thereby ensuring the purity and quality of the fluid.

4. Prevent the collapse of the pump tube: In micro peristaltic pumps, the pump tube usually has a certain degree of elasticity. Without proper back pressure, the pump tubing may collapse or deform, affecting fluid delivery. Appropriate back pressure can provide a certain amount of support and maintain the shape and integrity of the pump tube.

How to choose and use a micro peristaltic pump according to the actual situation?

The selection and use of micro peristaltic pumps requires many considerations based on the actual situation:

1. First, the actual needs need to be clarified, including the properties of the fluid, flow requirements, usage environment, etc. According to actual needs, you can choose the appropriate micro Peristaltic Dosing Pump model and specifications.

2. Consider the properties of the fluid, including whether the fluid contains particulate matter, acidity, alkalinity, corrosiveness, organic solvents, etc. According to the properties of the fluid, select pump heads and hoses with compatible materials, corrosion resistance, and wear resistance to ensure long-term stable operation.

3. Consider the flow requirements and select a Peristaltic Water Pump with appropriate flow rate according to the actual flow range required. Selecting a flow rate that is too small may not meet the usage needs, while selecting a flow rate that is too large may cause energy waste and additional noise.

4. Consider the use environment, including temperature, humidity, dustproof and other requirements, and select a micro peristaltic pump with appropriate protection level and waterproof function to meet the needs of the use environment.

5. You also need to pay attention to the voltage, current, noise and other parameters of the micro peristaltic pump. Choose the appropriate voltage and current according to actual needs, and consider the impact of noise on the surrounding environment.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.