What is the pumping capacity of a Solenoid Pump?

The pumping capacity of a mini solenoid water pump mainly refers to the flow and pressure it can provide. Specifically, the pumping capacity is determined by multiple factors such as pump design, electromagnetic drive efficiency, and material selection.

Firstly, the design of the pump determines the size and shape of its internal flow channel, which directly affects the liquid flow rate that the pump can handle. For mini electromagnetic pumps, despite their compact size, they can still achieve relatively high flow output through optimized flow channel design.

Secondly, the efficiency of electromagnetic drive has a significant impact on pumping capacity. Efficient electromagnetic drive can quickly and accurately respond to control signals, enabling the pump to stably output the required flow and pressure. Mini electromagnetic pumps typically use advanced electromagnetic technology and materials to ensure their driving efficiency reaches a high level.

In addition, material selection also affects pumping capacity. Wear resistant and corrosion-resistant materials can prolong the service life of pumps and reduce performance degradation caused by wear or corrosion. Therefore, when manufacturing mini electromagnetic pumps, materials with good wear resistance and corrosion resistance will be selected to ensure their long-term stable pumping capacity.

How can a mini electromagnetic pump achieve efficient pumping capacity?

The mini electromagnetic pump can achieve efficient pumping capacity mainly due to its unique working principle and carefully designed structure.

Firstly, the working principle of the mini electromagnetic pump is based on electromagnetic induction and liquid hydrodynamics. When current passes through an electromagnetic coil, a magnetic field is generated, which exerts a magnetic effect on the iron core, causing it to be attracted and move towards the direction of the electromagnetic coil. During this process, electromagnetic force directly acts on the internal mechanism of the pump, achieving efficient energy conversion. Meanwhile, the flow of liquid is achieved through the lifting and lowering of the valve core, which reduces the loss of energy transfer and improves pumping efficiency through direct driving.

Secondly, the structural design of the mini electromagnetic pump also fully considers the pumping efficiency. Its compact structure and tight fitting between components reduce fluid leakage and resistance inside the pump. In addition, the material selection of the pump has also been carefully considered to ensure its good wear and corrosion resistance, thereby extending the service life of the pump and maintaining efficient pumping capacity.

In addition, mini electromagnetic pumps usually have good dynamic adjustment characteristics. This means that the pump can adjust the output flow rate and pressure according to actual needs, avoiding unnecessary energy waste and further improving pumping efficiency

Technical Specification

| Model | DYX-SPS-01

| Voltage

| AC120V 60HZ

|

Pressure

| 1.2-2.2bar

| Power

| 11-15W

|

Noise

| <60dB

| Life cycle

| 1000 hours

|

| Media | Water | Application | electric steam mop, steam iron, steam cleaner, garment steamer, steam microwave oven, portable air conditioner and coffee machine.

|

Why can a Micro Solenoid Water Pump be used for steam mops?

The main reasons why mini electromagnetic pumps can be used for steam mops are as follows:

1. Efficient pumping capacity: The Solenoid Water Pump has efficient pumping capacity, which can quickly pump water or other liquids into the heating part of the steam mop. This provides a continuous and stable steam supply for the steam mop, ensuring cleaning effectiveness.

2. Compact design: Mini electromagnetic pumps typically have a compact design, compact size, and easy integration into steam mops. This design makes the steam mop more lightweight and convenient for users to carry and use.

3. Stable performance: The mini electromagnetic pump has stable performance during operation, providing constant flow and pressure. This allows the steam mop to maintain a stable steam output during the cleaning process, thereby improving the cleaning effect.

4. Easy to control: Mini electromagnetic pumps can usually control their pumping flow and pressure by adjusting the voltage and frequency of the power supply. This allows the steam mop to be adjusted according to different cleaning needs, achieving more flexible and efficient cleaning.

How can a dc 24v solenoid pump achieve continuous liquid circulation in a steam mop?

1. Pumping process: When the steam mop is turned on, the High Pressure Solenoid Pump starts working. Electromagnetic force drives the rotor inside the pump to rotate, generating suction. This suction force causes the water in the storage tank to be sucked into the pump body.

2. Pressure pushing: As the rotor continues to rotate, the water inside the pump body is compressed and pushed to the heating element. During this process, water is subjected to pressure, thereby achieving flow from the water storage tank to the heating element.

3. Heating generates steam: The water pushed to the heating element is rapidly converted into steam after heating. During this process, the heating element is usually an electrified resistance wire or infrared radiator, which can quickly raise the water temperature above the boiling point.

4. Steam supply: The generated steam is released through the nozzle or steam outlet of the steam mop for cleaning the ground or other surfaces.

5. Reflux and recirculation: After steam is released, some steam condenses into water, which is usually returned to the storage tank through the design of a steam mop. At the same time, the new water in the storage tank will also be continuously sucked in by the mini electromagnetic pump and the above process will be repeated, thereby achieving continuous liquid circulation.

6. Control system adjustment: The control system of the steam mop will monitor parameters such as steam temperature, pressure, and flow, and adjust the working status of the electromagnetic pump as needed. For example, if the steam flow rate is insufficient, the control system may increase the power or speed of the electromagnetic pump to improve the extraction and pushing speed of water.

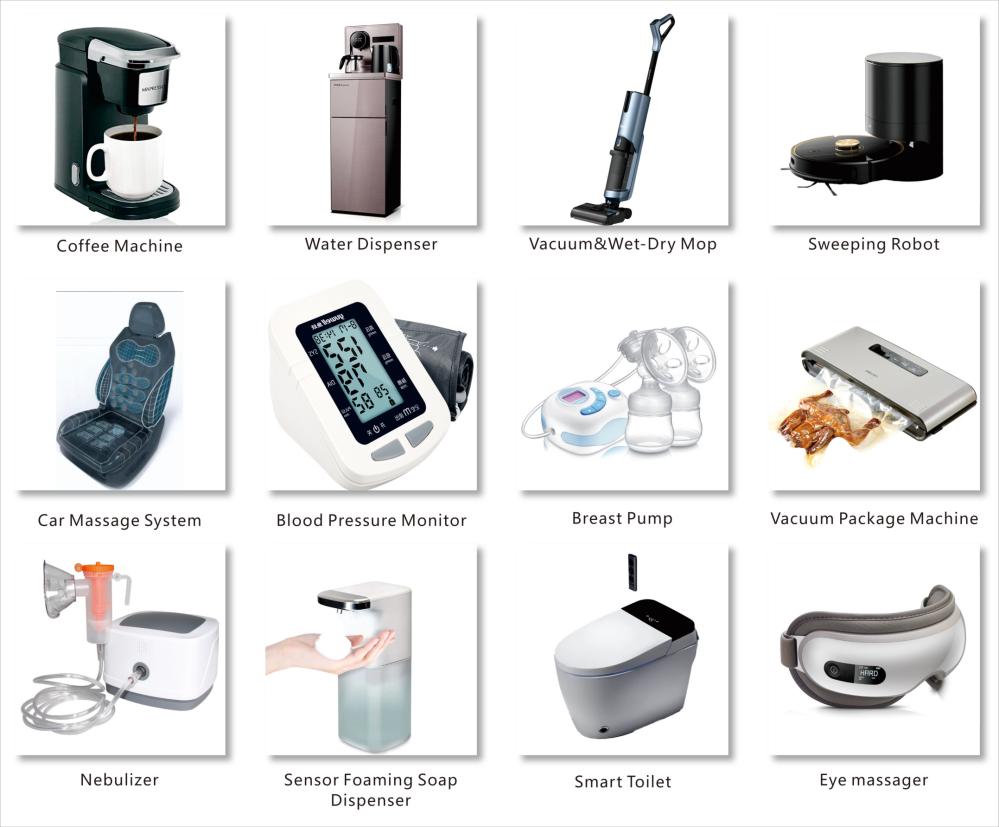

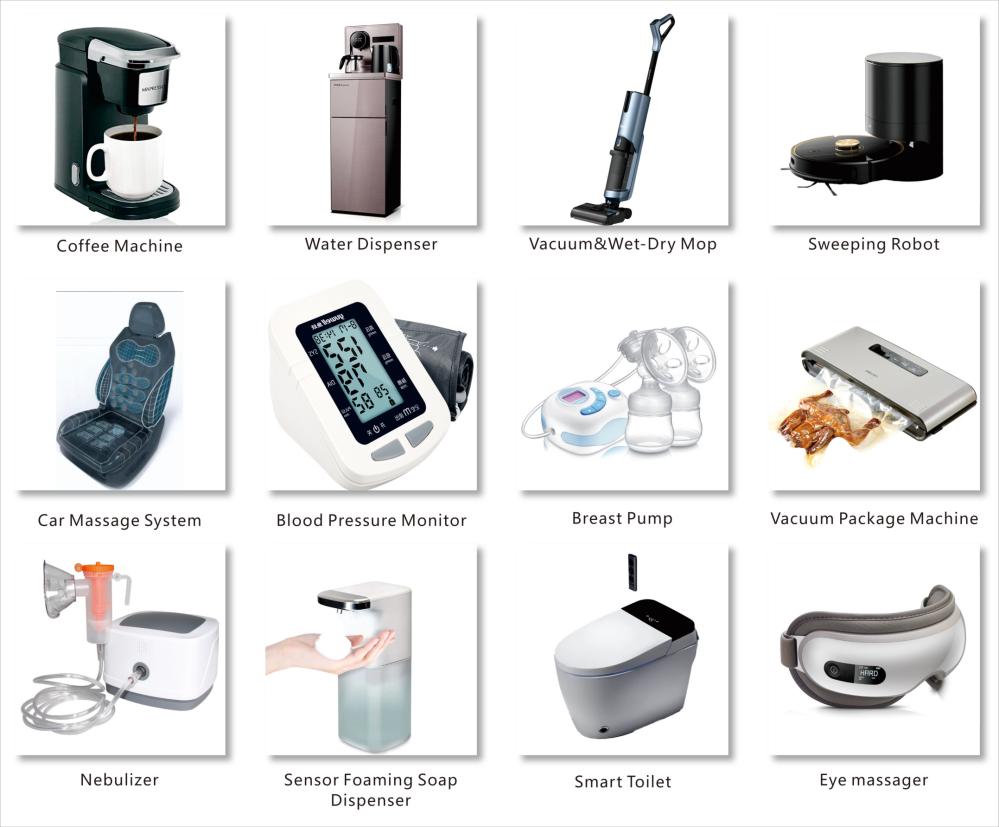

DYX Mini Pumps And Solenoid Valves Application

What is the role of a cleaning solenoid pump in a steam mop?

The role of an electromagnetic pump in a steam mop: In a steam mop, the mini electromagnetic pump is used to extract water from the water storage tank and generate steam by heating the heating element. Steam mops are usually equipped with temperature and pressure sensors, which can monitor the temperature and pressure of steam in real time to ensure a stable supply of steam.