What is the difference between a micro vacuum pump and a Suction Pump?

Micro diaphragm vacuum pumps and suction pumps are both devices used for processing fluids or gases, but they are limited in design, working principles, and application scenarios

There is a significant difference on Mini Vacuum Pump is a special type of pump designed to generate vacuum or low-pressure environments. It usually has a diaphragm that moves inside the pump, changing the volume inside the pump and generating suction or pressure. This type of pump is usually used for high vacuum requirements or low-pressure applications, such as scientific research experiments, medical equipment, food packaging, etc.

And suction pumps, also known as pumps, are mainly used to move liquids from one place to another. It usually has a rotation impeller or piston, through mechanical action, causes liquid to flow. This type of pump is widely used in household, agricultural, and industrial fields, such as irrigation and cleaning,water supply, etc.

Technical Specification

| Model | DQB421-FB | Voltage | DC6V 12V 24V |

| Current | 1000mA 550mA 300mA | Air Flow | 5-6LPM |

| Pressure | 600-850mmHg | Maximum vacuum pressure | -550mmHg |

| Leakage | smaller than 15mmHg | Life span | more than 400 hours |

The advantages of micro diaphragm vacuum pumps mainly include:

1. No need for lubricating oil: The DC Electric Vacuum Pump does not require lubricating oil during operation, so it will not pollute the working environment.

2. Simple and compact structure: Its design makes the pump body compact, and installation and maintenance are relatively simple.

3. Wear resistance and long service life: Due to the fewer moving parts of the diaphragm pump, it is relatively more wear-resistant and has a longer service life.

4. Can be used in high vacuum environments: Micro diaphragm vacuum pumps can meet the needs of high vacuum, so they are widely used in certain scientific research, medical and other fields.

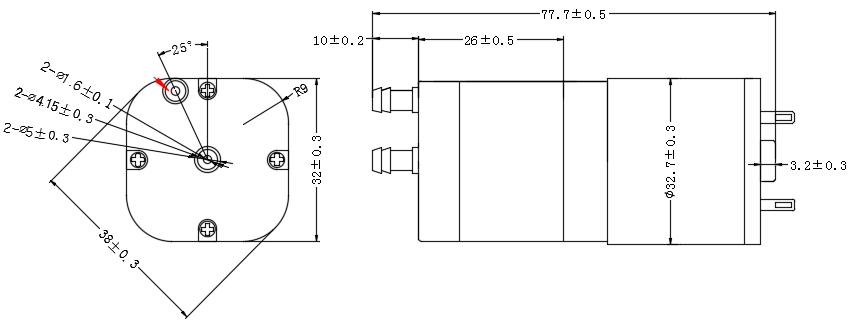

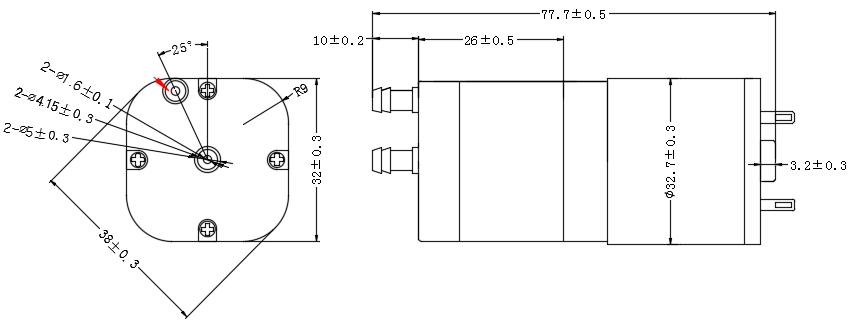

Dimension Drawing

What are the drawbacks of micro diaphragm vacuum pumps?

1. Flow limitation: Due to its structure and working principle, the flow rate of small electric vacuum pumps is relatively small.

2. It can only run at intervals and cannot run for long periods of time

3. Limited pumping capacity: Due to its small size, the Portable Vacuum Pump has limited pumping capacity and cannot handle large amounts of gas or liquid.

Flow Chart

What are the principles and structures of micro diaphragm vacuum pumps and suction pumps?

The principle of a Small Electric Vacuum Pump is mainly to use the circular motion of the motor to make the diaphragm inside the pump move back and forth through a mechanical device. This movement compresses and stretches the air inside the pump chamber, forming a vacuum, thereby creating a pressure difference with the external atmospheric pressure at the suction port. Under the pressure difference, gas is sucked into the pump chamber and then discharged from the exhaust port. Its structure usually includes components such as motor, eccentric shaft, elastic diaphragm, pump body, etc. Among them, the elastic diaphragm is the core component, which performs linear reciprocating motion under the drive of the motor, achieving the extraction and discharge of the medium.

The principle of a suction pump (usually a centrifugal pump) is to use the rotational motion of the impeller to suck the liquid in from the inlet, and then push the liquid towards the outlet through the rotation of the impeller. Its structure usually includes components such as pump body, impeller, bearings, seals, etc. The internal design of the pump body allows the liquid to be subjected to centrifugal force upon entering the impeller, which in turn pushes it towards the outlet. The rotational motion of the impeller is driven by an electric motor through bearings.

DYX Mini Pumps And Solenoid Valves Application

In which application scenarios cannot micro diaphragm vacuum pumps and suction pumps be interchanged?

1. High vacuum requirements: Micro diaphragm vacuum pumps, due to their design characteristics, can generate high vacuum, and are widely used in situations that require high vacuum, such as scientific research experiments, medical instruments, etc. However, suction pumps are usually not suitable for applications that require high vacuum levels, as their design and working principle cannot achieve such high vacuum levels.

2. Liquid properties: The suction pump is mainly used for conveying liquids and has good adaptability to different liquid properties (such as viscosity, corrosiveness, volatility, etc.). Although micro diaphragm vacuum pumps can also be used to process certain liquids, they are mainly designed to generate vacuum or low-pressure environments and may not be suitable for certain liquids with specific properties.

3. Noise and vibration requirements: Some application scenarios have strict requirements for noise and vibration, such as laboratories, medical facilities, etc. Micro diaphragm vacuum pumps are usually more popular in these situations due to their relatively low noise and vibration levels. The suction pump may produce significant noise and vibration, making it unsuitable for use in these demanding situations.

4. Space limitation: In certain space limited application scenarios, such as micro devices, portable instruments, etc., micro diaphragm vacuum pumps may be more suitable due to their compact structure and small volume. However, suction pumps are usually larger in volume and may not be suitable for these limited space situations.