DYX diaphragm electric liuqid transfer pump product

$2-4 /Piece/Pieces

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Min. Order: | 1000 Piece/Pieces |

| Transportation: | Ocean,Air |

| Port: | Shenzhen |

$2-4 /Piece/Pieces

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Min. Order: | 1000 Piece/Pieces |

| Transportation: | Ocean,Air |

| Port: | Shenzhen |

Model No.: DSB413-G-5

Brand: DYX

Current: <250mA

Water Flow Rate: >1.4L/Min

Media: Water

Life Cycle: >30,000cycles

Working Temperature: 5-55

N.W: 37g

Noise: <60dB

Voltage: DC2.8V,DC4.0V,DC6.V

| Selling Units | : | Piece/Pieces |

| Package Type | : | Inner package :35pcs/plate, weight:148g, size:425x520x40mm Outer package: 350pcs/box, weight:990g, size: 445x525x325mm |

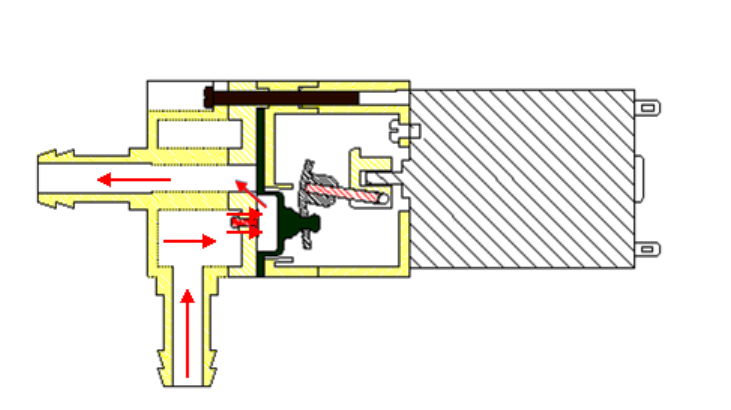

The working principle of Mini Liquid Pump is as follows:

1. Pump body: The pump body of a Mini Diaphragm Pump usually consists of two interconnected chambers, namely the suction chamber and the discharge chamber. The suction and discharge chambers are separated by a flexible diaphragm.

2. Diaphragm: The diaphragm is the core component of the Micro diaphragm pump and is usually made of elastic materials such as rubber or polytetrafluoroethylene (PTFE). The function of the diaphragm is to completely isolate the suction chamber and the discharge chamber to prevent the liquids from mixing with each other.

3. Suction valve and discharge valve: The suction valve and discharge valve are located at the inlet and outlet of the suction chamber and discharge chamber respectively. Their function is to control the flow direction of the liquid so that the liquid can only flow from the suction chamber to the discharge chamber, but not in the reverse direction.

4. Driving device: The driving device of the Small Diaphragm Pump can be compressed air or an electric motor. When compressed air is used as the driving force, the diaphragm is controlled to move back and forth between the suction chamber and the discharge chamber through the inlet and outlet control of the compressed air. When an electric motor is used as the driving force, the diaphragm moves back and forth between the suction chamber and the outlet chamber through the transmission of the connecting rod and crankshaft.

5. Working process: When the diaphragm pump starts to work, the driving device starts to operate, causing the diaphragm to move back and forth between the suction chamber and the discharge chamber. As the diaphragm moves toward the suction chamber, the suction valve opens and liquid is sucked into the suction chamber. During the movement of the diaphragm toward the discharge chamber, the suction valve is closed, the discharge valve is opened, and the liquid is discharged from the chamber. With the continuous reciprocating motion of the diaphragm, the liquid is continuously sucked in and discharged, achieving the normal operation of the pump.

Technical Specification:

| Voltage | DC2.8V DC 4V DC 6V | Current | 600mA,350mA,250mA |

| Flow rate | 1.4LPM | Media | Water,air |

| Maximum vacuum pressure | -15kPa | Life cycle | 30000 cycles |

| Noise | 60dB | Weight | 50g |

What materials do you need to make a Mini DC Water Pump?

1. Motor

The motor of the Micro Water Pump usually uses a brushless DC motor, which has the characteristics of small size, light weight, high efficiency and low noise. The motor's housing is usually made of aluminum alloy or stainless steel, which resists corrosion and wear. The motor's coils and electronic components need to be able to withstand environmental factors such as high temperature and humidity.

2.Steel balls

The steel balls of the Mini DC Liquid Pump are used to push the diaphragm to move. Steel balls are generally made of high carbon steel or stainless steel, which have high hardness and wear resistance. The surface of steel balls needs to be polished to improve lubrication performance and reduce friction coefficient.

3.Steel needle

The steel needle of the Mini DC Electric Pump is used to fix the rubber tower and one-way valve. Steel needles are generally made of stainless steel, which has high strength and high corrosion resistance. steel needle

The surface needs to be polished to improve lubrication performance and reduce friction coefficient.

4 rotors

The rotor of the micro diaphragm water pump is one of the key components used to drive the movement of the diaphragm. The rotor is generally made of high-strength stainless steel, which has high hardness and wear resistance

sex. The surface of the rotor needs to be polished to improve lubrication performance and reduce friction coefficient.

5. Rubber Tower

The rubber tower of the micro diaphragm water pump is one of the main components used to separate the liquid into two parts. Rubber towers generally use corrosion-resistant and wear-resistant rubber materials

Made of natural rubber, nitrile rubber, etc. The rubber tower needs to have good elasticity and sealing properties to ensure the stability and life of the diaphragm.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.