How does the Micro Water Pump work in the hydrogen generator?

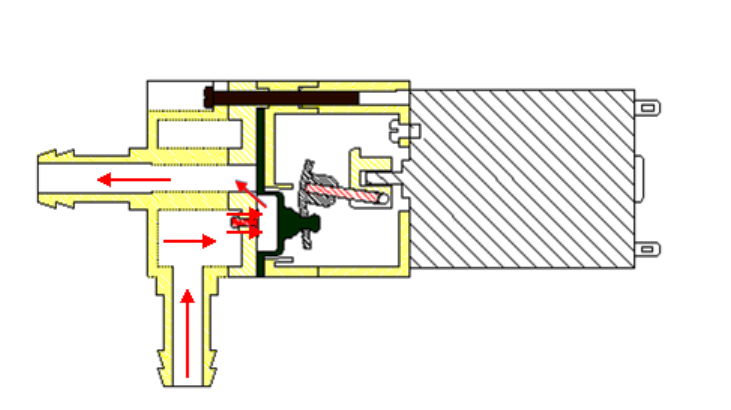

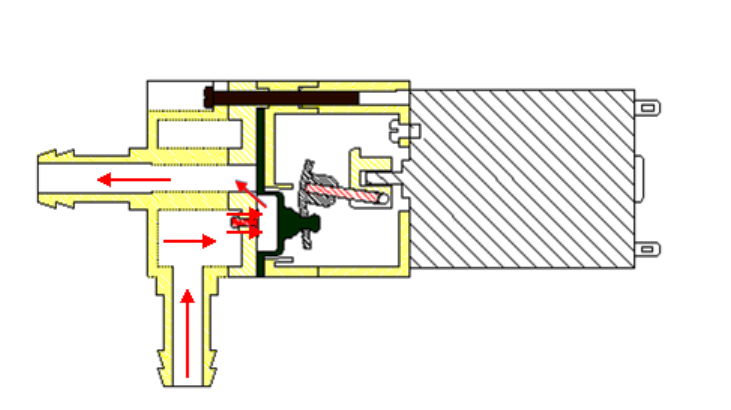

Starting and driving: When the hydrogen generator starts working, the motor of the Mini Water Pump starts. The circular motion of the electric motor is converted into a reciprocating motion of the diaphragm by a mechanical device. Formation of negative pressure and water absorption: As the diaphragm moves outward, the pressure in the pump chamber decreases, forming negative pressure. This negative pressure causes the suction valve to open and water is sucked into the pump chamber from the water storage container or water inlet.

Formation of positive pressure and drainage: When the diaphragm moves inward, the pressure in the pump chamber rises, forming positive pressure. At this time, the suction valve is closed to prevent water from flowing back, and the discharge valve is opened, and the water in the pump chamber is pushed toward the electrolyzer.

Circulating water supply: As the motor continues to rotate, the diaphragm continues to reciprocate, forming a stable water circulation between the water inlet of the hydrogen generator and the electrolyzer. This cycle ensures that there is sufficient and stable water in the electrolytic cell for the electrolysis reaction.

Auxiliary exhaust and heat dissipation: During the electrolysis process, in addition to hydrogen and oxygen, some gases and heat may also be generated. The circulating water flow of the micro diaphragm water pump also helps to take away these gases and heat to maintain the stable operation of the electrolyzer.

What is the main function of Self Priming Micro Water Pump used in hydrogen generator?

In the hydrogen generator, the specific function of the Mini Hydraulic Pump is mainly to provide the necessary liquid circulation or transportation function for the hydrogen production process.

Hydrogen generators typically involve the process of electrolysis of water, which is the production of hydrogen by splitting water into hydrogen and oxygen. In this process, the main function of the miniature hydraulic pump is to transport water from the water storage container or water source to the electrolyzer to ensure the continuous progress of the electrolysis process.

Specifically, the Membrane Water Pump reciprocates through its internal diaphragm to pump water into the electrolytic tank, and after the electrolysis is completed, the generated hydrogen and oxygen are discharged from the electrolytic tank. In this way, a complete liquid circulation and gas generation process is formed.

In addition, the micro diaphragm water pump can also adjust its delivery flow and pressure according to the needs of the hydrogen generator to meet the requirements of different hydrogen production processes.

How does the dc electric hydraulic pump ensure the continuous progress of the electrolysis process?

1. Stable water flow supply: The Mini Liquid Pump reciprocates through its internal diaphragm, which can stably pump water from the water storage container or water source to the electrolyzer. This stable water supply is the basis for the continuous electrolysis process.

2. Strong adaptability: The mini dc hyraulic pump can adjust its delivery flow and pressure according to the needs of the hydrogen generator. This means that it can flexibly adapt to different electrolysis process requirements, ensuring that the electrolysis process can proceed stably under different conditions.

3. Reliable sealing performance: The micro diaphragm water pump adopts a strict sealing design, which ensures that the pump will not leak during operation. This is crucial to prevent leakage of electrolyte into the external environment and the risk of explosions caused by mixing hydrogen with oxygen.

Technical Specification

| Model | DSB412-H | Voltage | dc12v |

| Current | 700mA | Flow | 300mlpm |

| Media | Water | Net weight | 62g |

| Noise | 60dB | Life span | 100000 cycles |

How does a portable hydraulic pump ensure a stable water supply?

Micro diaphragm water pumps ensure a stable water supply by:

1. Reciprocating motion mechanism: The core of the DC Diaphragm Water Pump is the reciprocating motion mechanism of the diaphragm. This mechanism causes the volume within the pump chamber to periodically increase and decrease, thereby producing a continuous flow of water during the suction and discharge processes.

2. Inlet and outlet valves: The water pump is equipped with inlet and outlet valves, which open and close at different stages of diaphragm movement to ensure the orderly flow of water. When the diaphragm moves upward, the inlet valve opens and liquid is sucked into the pump chamber; when the diaphragm moves downward, the outlet valve opens and liquid is discharged from the pump chamber.

3. Motor control: The continuous rotation of the motor drives the reciprocating motion of the diaphragm, thereby maintaining the continuity of the water flow. The motor can adjust the pump's flow rate to suit different needs by controlling its rotational speed.

4. Sealing performance: The micro diaphragm water pump has good sealing performance to ensure that no leakage occurs during the pumping process. This ensures the stability and continuity of water supply.

5. Wear-resistant materials: Diaphragms and other key components are usually made of wear-resistant materials to withstand the wear and tear caused by long-term operation and frequent use. This helps maintain the performance of the water pump and extend its service life.

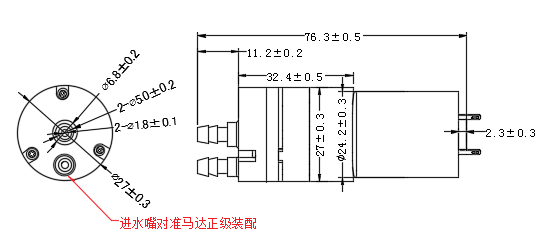

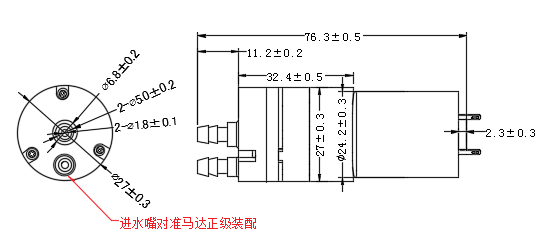

Diemension Drawing Size:mm

How to control the rotation of the motor of a DC Liquid Pump to achieve the purpose of adjusting the flow rate?

1. Voltage control: By changing the power supply voltage of the motor, the speed of the motor can be controlled. The higher the voltage, the faster the motor rotates and thus the greater the flow rate of the pump. Therefore, regulation of flow can be achieved by adjusting the supply voltage or using a variable voltage power supply.

2. PWM (pulse width modulation) control: This is a common electronic control method that controls the average current by changing the pulse width of the motor power supply, thereby controlling the motor speed. By adjusting the duty cycle of the PWM signal, precise control of the flow rate can be achieved.

3. Frequency converter control: The frequency converter is a device that can change the power supply frequency of the motor. By changing the power supply frequency of the motor, the speed of the motor can be controlled. Using a frequency converter, the flow rate can be adjusted smoothly and precisely controlled as needed.

4. Mechanical speed regulation: In some cases, the speed of the motor can also be adjusted mechanically, such as using a speed regulator or clutch. These methods, while relatively simple, may not be as precise and flexible as electronic control methods.